SAFFiRE Sustainable Aviation Fuel Project Earns Government-Industry Boost

With fuel prices soaring, a new government–industry partnership based at the National Renewable Energy Laboratory (NREL) plans to shift the aviation market further away from oil fields and closer to the farmlands.

The planned 10-ton-per-day pilot plant project, Sustainable Aviation Fuel From [i] Renewable Ethanol, or SAFFiRE, involves D3MAX LLC, the U.S. Department of Energy (DOE) Bioenergy Technologies Office (BETO), Southwest Airlines, NREL, LanzaJet, and other partners. The results could help make the goals of the multiagency Sustainable Aviation Fuel Grand Challenge a reality.

“NREL’s many years of expertise converting biomass into fuels and chemicals is crucial to SAFFiRE’s goal of achieving an annual production capacity of 7 billion gallons of sustainable, low-carbon aviation fuel by 2040,” said Mark Yancey, project principal investigator (PI), NREL alumnus, and SAFFiRE Renewables CEO.

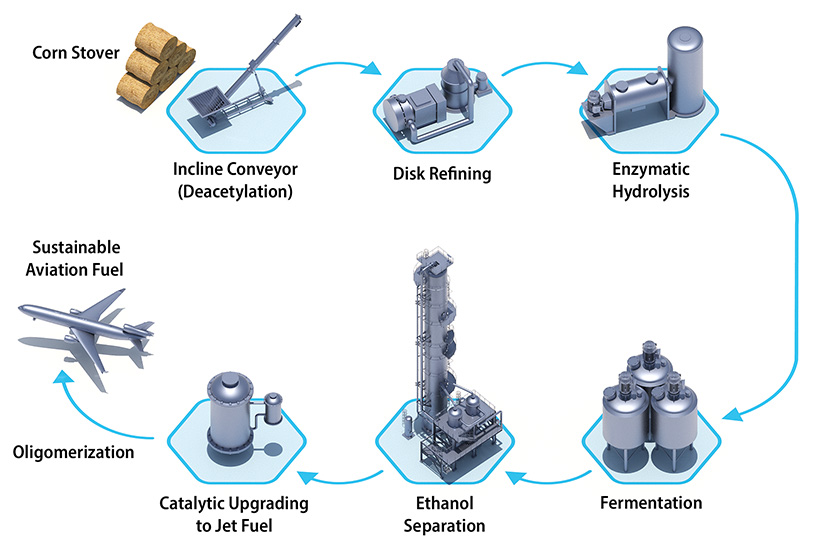

“SAFFiRE is the capstone of several NREL applied science projects,” said Michael Himmel, project co-PI and NREL senior research fellow. “It plans to turn an agricultural waste product of little value—corn stover—into profitable and environmentally friendly fuels.” What makes the project so unique is the combination of D3MAX’s commercial sugar production and ethanol fermentation technology and NREL’s patent-pending deacetylation and mechanical refining process, or DMR.

NREL’s DMR alkaline biomass pretreatment step, coupled with enzymes from Novozymes, essentially seeks to solve the problem of how to efficiently break down corn stover waste to sugars that can then be converted to fuels. Unlike acidic pretreatment, DMR operates under low temperature and low pressure, does not produce toxic byproducts, and is therefore more reliable and less expensive than other methods. SAFFiRE could be positioned to take advantage of the infrastructure of more than 200 existing ethanol plants and equipment already found on many farms across the nation.

“Southwest Airlines is thrilled to partner with NREL, DOE, and D3MAX to advance what we believe could be game-changing technology to be used by SAFFiRE,” said Michael AuBuchon, senior director Fuel Supply Chain Management at Southwest Airlines. “This first-of-its-kind investment for Southwest furthers our efforts to support the commercialization of affordable, lower-carbon SAF—on a life-cycle basis compared to conventional jet fuel—which can help the aviation industry reach its ultimate goal of carbon neutrality by 2050.”

NREL scientists already proved the process is effective in the lab and at small pilot scale—techno-economic and life-cycle analysis shows that the SAF from SAFFiRE could be less expensive than petroleum-based jet fuel and could reduce carbon intensity by up to 84% compared to conventional jet fuel.

Nancy Dowe, the lead fermentation scientist on the project, has worked with Himmel on the project since its inception. NREL researcher Xiaowen Chen, the lead pretreatment process engineer, was a key innovator of the DMR process along with Himmel, Melvin Tucker, and Rick Elander. Tucker and Elander are both recently retired from NREL.

"In the next 3 1/2 years we will work to demonstrate that this technology is ready for commercialization,” Himmel said.

Lincolnway Energy, a corn ethanol plant located in Nevada, Iowa, plans to host the SAFFiRE pilot project. “Integration of the SAFFiRE process with existing ethanol plants is a key aspect of our commercialization plan,” Yancey said. SAFFiRE’s plan is to ship the finished renewable ethanol product to LanzaJet’s alcohol-to-jet facility in Georgia where it will be converted to SAF. The goal is that the SAF could be used to fuel future Southwest Airlines flights.

Funds were initially provided in 2021 through BETO’s “Scale-up Funding Opportunity.” The recent addition of a 50% investment match from Southwest Airlines could help speed up the steps to get from large-scale pilot testing to market, thus making the commercial production of SAF from biomass more likely in the not-so-distant future.

Last Updated Jan. 22, 2026