Silicon Anode Research Offers Pathway to Increased Driving Range for Electric Vehicles

A new National Renewable Energy Laboratory (NREL)-led multi-lab consortium addresses critical barriers to the development of smaller, cheaper, and better performing lithium-ion (Li-ion) batteries for electric vehicles (EVs) by investigating the use of silicon as an alternative to graphitic carbon anode material. This initiative combines the forces of the Silicon Electrolyte Interface Stabilization (SEISta) project and the Silicon Deep Dive efforts under one mission, the Silicon Consortium Project (SCP).

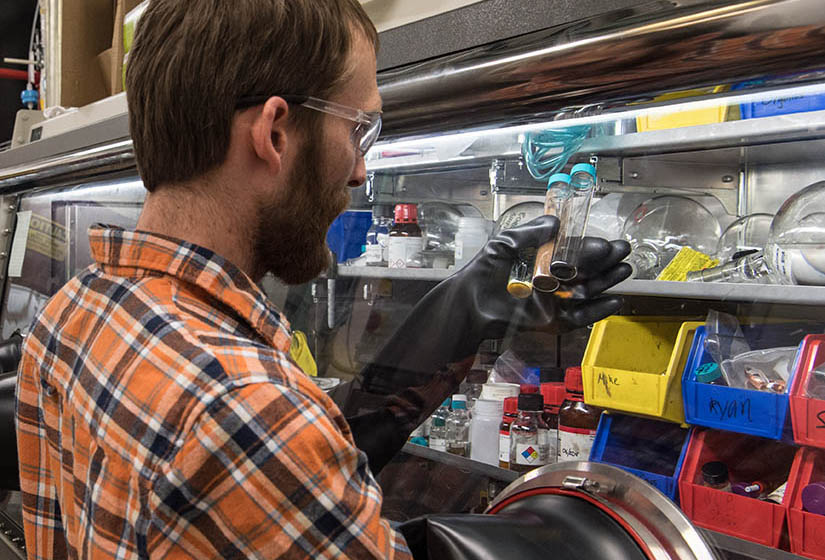

Funded by the U.S. Department of Energy's Vehicle Technologies Office, the NREL-led consortium includes researchers from Argonne, Sandia, Oak Ridge, Pacific Northwest, and Lawrence Berkeley national laboratories. This multidisciplinary team focuses on understanding the formation and evolution of the solid electrolyte interphase (SEI) to solve the calendar-life challenge—or the number of years a battery is expected to last—currently limiting the development of silicon anodes.

Together, the national laboratories employ advanced characterization techniques coupled with state-of-the-art research facilities to explore the foundational science of organic electrolytes with silicon interfaces to develop the full electrode and cell chemistry. Researchers aim to use these findings to take advantage of silicon's ability to store more than 3,500 milliamp hours per gram, which could reduce battery pack size by 25%–30%, or increase driving range by 30%–40% with packs the same size as those found in current EVs.

While there is potential to improve EV performance, the extent and application of silicon in Li-ion batteries is still largely unknown. Researchers' primary concerns include studying the stability of silicon electrodes and improving SEI performance, which is the layer of material that forms between the anode and the liquid electrolyte in a battery cell. Over the years, SEISta and Silicon Deep Dive researchers have focused on better understanding the nature of the SEI through materials standardization, modeling, and SEI characterization.

Researchers across the multi-lab SEISta team learned more about the SEI through thermal evolution, Zintl phase stabilization, mechanical properties, and the interphase's chemical properties. SEISta researchers developed plasma-prepared model silicon copper wafer samples with controlled oxide coatings to study SEI samples across all facilities of partnering national laboratories. With standardized samples shared amongst the laboratories, researchers focused on understanding the mechanical and chemical properties of this critical silicon-electrolyte interface.

Within the Silicon Deep Dive project, researchers focused on establishing baseline silicon materials to implement a silicon-based anode in a lithium-ion cell. These efforts included a wide range of electrochemical, chemical, and structural characterization of the system across length- and timescales. Researchers developed specialized characterization techniques, including neutron diffraction studies, MAS-NMR, optical spectroscopy methods, and X-ray based techniques.

One of the main challenges facing silicon anodes is the inherent reactivity that occurs as lithium enters the electrode of the battery, otherwise known as lithiation. The lithium silicide phases—which form upon lithiation—react with various battery components, including binders, electrolytes, additives, and even moisture and air, causing a loss of lithium. This lithium loss is a significant contributor to the degradation of the cell, compromising battery life. Together, SEISta and the Silicon Deep Dive program experimented with the addition of salts and electrolyte solvents to aid in the surface stability of the anodes and developed a method to passively release excess lithium during the formation of the SEI to stabilize the reaction and prolong the lifetime of the battery.

Early Assessment of Silicon Cells May Predict Calendar Life

The new SCP collaboration has led to the development of a preliminary assessment method to measure the calendar lifetime of cells in under two weeks by holding the voltage of silicon cells at the top of their charge. Researchers traditionally perform calendar-life testing of battery cells over multi-month timeframes. However, the new test protocols allow the SCP to assess the progress of silicon modifications, cell designs, electrolytes, or additives faster and more efficiently. This new protocol will streamline research, allowing researchers to rapidly determine their modifications’ efficacy. This method should enable faster elimination of unproductive approaches to stabilize the silicon SEI and improve calendar life.

The overall goal of the SCP is to enable full cells with Si-based anodes that deliver 1,000 cycles at C/3 rate of discharge, have useable energy greater than 375 Wh/kg, an energy density above 750 Wh/L, and a calendar life of more than 10 years. In short, researchers hope the addition of silicon cells can supply reliable power to move EVs further and faster for years to come.

Learn more about NREL's transportation research and energy storage research.

Last Updated Jan. 22, 2026