Energy Department Launches $4.65M Geothermal Prize Through American-Made Challenges

Prize Aims to Strengthen Bonds Between Additive Manufacturing and Geothermal Industries

The American-Made Challenges program is giving a boost to geothermal energy by bringing the additive manufacturing and geothermal industries together in its newest competition—the American-Made Geothermal Manufacturing Prize.

This latest prize was announced in January and officially launched on April 29, 2020. Competitors will participate in four successive contests, each lasting between three and seven months and offering progressively higher cash and voucher incentives. The prize will span 18 months total and is expected to culminate in the summer of 2022.

Like all American-Made Challenges, the Geothermal Prize is designed to bolster American energy innovation. The Geothermal Prize brings together competitors with new ideas for operating within harsh geothermal environments and rapidly funnels teams through a series of phases designed to foster collaboration, networking, and education. The winners will emerge from the prize with market-ready geothermal solutions.

“One exciting aspect about this prize is that we are targeting two groups and trying to bring them together,” said Sarah Gomach, Geothermal Prize program lead at NREL. “One group is people who have experience in geothermal but limitations in tooling or components, but they also have an idea to improve it. The second group is the additive manufacturing community—a big part of this prize is bringing manufacturing advancements to the geothermal community.”

The Geothermal Prize is unique in its partnership structure. The U.S. Department of Energy’s Geothermal Technologies Office and Advanced Manufacturing Office are both funding the prize, and the National Renewable Energy Laboratory (NREL) is administering the competition.

This time, however, NREL is not the only national laboratory involved. For the first time in the American-Made Challenges’ history, the Energy Department’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory will serve as a technical partner. Like some of the other prizes, the Geothermal Prize will issue technical support vouchers redeemable at any national laboratory. Exclusive to this prize is that it leverages the specific expertise of Oak Ridge researchers in additive manufacturing for geothermal to help the competitors during the course of the prize.

“We have informally partnered with other labs in other prizes through vouchers,” Gomach said. “Yet, we’ve never had another lab on board to offer additional depth of tech experience, consulting time, and design consultation. Oak Ridge will participate throughout the prize and play a large role between the first and second prize contests.”

Competition Structure

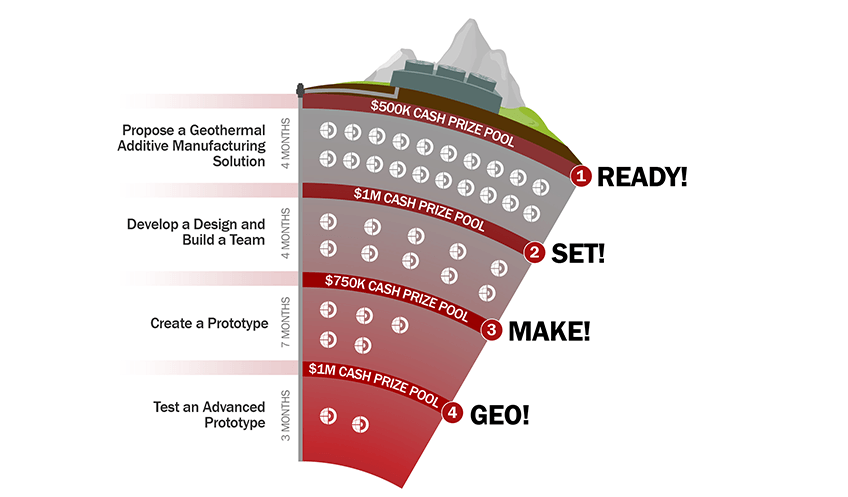

The phased contest structure is another way the Geothermal Prize is unique. Unlike other prizes with three contests, the Geothermal Prize is split into four contests: Ready!, Set!, Make!, and Geo!

Each contest will have a certain number of winners, and those winners—aside from advancing to the next contest—will receive money and vouchers to help them prepare their projects for the next contest. The Ready! Contest kicked off April 29, 2020; submissions will be accepted until Aug. 26, 2020. Between the end of August and an anticipated date in November, the prize administrators will select 20 winners to split $500,000. According to Gomach, as the Ready! winners prepare for the Set! Contest, Oak Ridge will play a key role and provide its most impactful contribution to the teams’ progression.

After the Set! Contest, 10 winners will split a total of $1 million and begin to build their prototypes for the Make! Contest. The selection committee will choose five winning teams from the Make! Contest to split $750,000 and test their prototypes in the Geo! Contest. From those five teams, the selection committee will name two final winners to split $1 million and move their projects to market. In total, the final two winners will receive $775,000 in cash prizes throughout the duration of competition.

“Moving the teams through milestones as quickly as possible reduces the R&D period from years to months,” Gomach said.

As far as where competitors can come from, Gomach explained that there are no real limitations.

“Anyone with an idea can compete,” she said. “It could be people in the oil and gas community or those with design experience. The possibilities are endless. When you ask for an ideal competitor, it is a really long list. It boils down to someone with a good idea that will benefit the U.S. geothermal industry.”

While the first contest is open during the next few months, Gomach expects the teams will undergo an education effort, where people with geothermal expertise will give basic background information to those with manufacturing expertise, and vice versa.

Geothermal Energy and Additive Manufacturing Technologies

The Geothermal Prize focuses on two communities: geothermal and manufacturing.

Geothermal resources are characterized by reservoirs of hot water found below the Earth’s surface. Companies drill to those reservoirs and bring hot water up to the surface to use for electrical generation, heating, and cooling. This energy can be harnessed around the clock, regardless of weather conditions, unlike other renewable energy sources. Geothermal power plants typically have a much smaller footprint than those required by coal, wind, and solar.

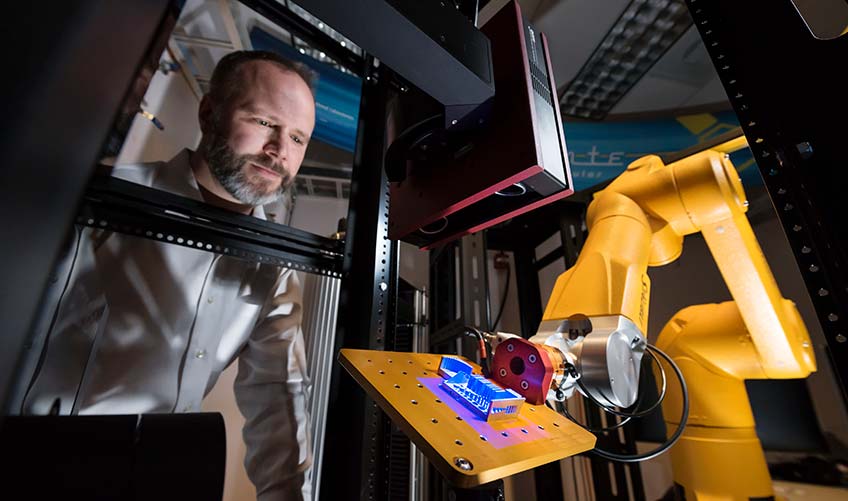

Additive manufacturing refers to multiple technologies, including 3D printing, rapid prototyping, and additive fabrication—technologies that “add” layer upon layer of material to create an incredibly precise end product. Additive manufacturing has already achieved many successes in areas such as the health care industry. This technology has demonstrated an ability to provide more flexibility and faster production of R&D models and medical devices. Advancements in prosthetics, patient-matched dental components, and tissue fabrication are just a few of note.

An important aim of the Geothermal Prize is to weave the technologies that enable these manufacturing advancements into the world of geothermal energy and provide similar boosts in development and manufacturing of geothermal technology components.

American-Made Challenges Prize Model

The acceleration and delivery to market of viable, new technologies is a central goal of the American-Made Challenges program. Grant funding, the popular funding alternative, has traditionally presented specific challenges to small startups with limited funding and, in some cases, little more than an idea.

What American-Made Challenges uniquely provide is an opportunity for startups to take a minimal initial investment, prepare a submission, and present their ideas directly to the Energy Department with the possibility of earning money faster to reinvest in and develop their ideas quickly. Winning teams take a varying sum of cash prizes and technical assistance vouchers to push their innovations across the finish line and accelerate their journey to the U.S. energy market.

The prize model also sets up a system of collaboration and networking that participants from many teams have said they found especially useful. This facet of the prize program, known as the American-Made Network, comprises universities, national laboratories, startup incubators, accelerators, facilities, investment firms, and other industry partners across the country. By connecting entrepreneurs with these organizations, the American-Made Challenges program allows for further collaboration opportunities across a wide array of sectors.

Learn more about the American-Made Geothermal Manufacturing Prize by visiting the website and attending the informational webinar on May 27, 2020.

Last Updated May 28, 2025