From Brainstorming to Breaking Ground: A Progress Report from the FAST Grand Prize Winners

Supporting a ramp-up of renewable power on the grid is a widely shared goal across the energy community. However, power generated from variable renewable sources, such as solar and wind, requires substantial energy storage and flexibility. Pumped-storage hydropower (PSH) can provide those key features, supporting the continued growth of renewables on the grid.

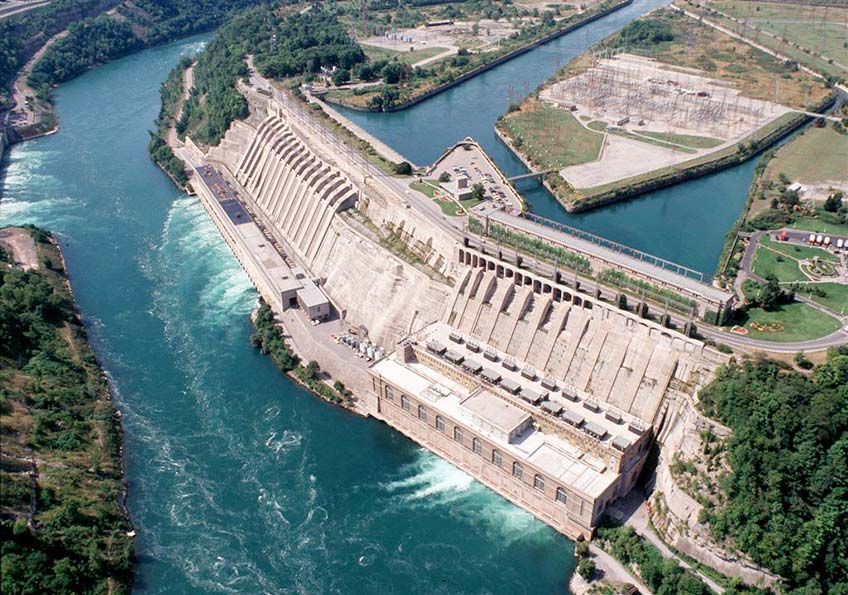

Ontario Power Generation's Sir Adam Beck Generating Complex, the largest source of hydroelectric power in Ontario. Image credit: www.opg.com

Developing PSH is currently a capital- and labor-intensive venture. To scale the barriers to PSH expansion, the U.S. Department of Energy’s (DOE’s) Water Power Technologies Office launched the Furthering Advancements to Shorten Time (FAST) Commissioning for Pumped-Storage Hydropower Prize.

FAST aims to solicit new ideas for how to shorten timelines and reduce the cost and risk of commissioning future PSH projects.

In October, DOE’s Office of Energy Efficiency and Renewable Energy Water Power Technologies Office awarded four teams $500,000 in cash and support to move their grand-prize-winning ideas forward.

In the months since, those four teams have been hard at work, continuing to advance their exciting PSH proposals. Let’s check in and see what these PSH pioneers are up to.

Accelerating PSH Construction with Steel Dams

Team Wittmeyer-Dasgupta of the Southwest Research Institute’s (SwRI’s) modular steel concept for dams claims to reduce costs by one-third and cut construction schedules in half.

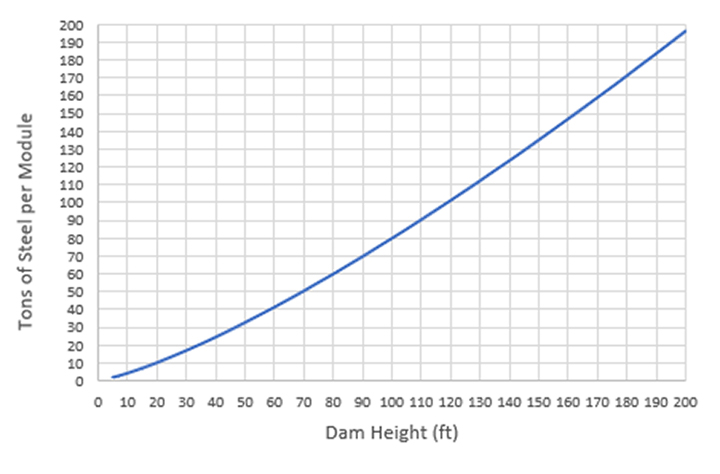

During the past several months, the team developed a method for optimally sizing a steel dam depending on the installed capacity and available head for an offline PSH facility.

The team produced a series of charts to assist developers in pinpointing their specific project needs in terms of PSH capacities and steel dam heights. From there, developers can choose which configuration is best suited for an upper reservoir site and which design will require the least structural and plate steel per module, thereby reducing construction costs.

Using Modern Tunnel-Boring Machines for Underground Pumped Storage

The Nelson Energy-Midwest Energy Recycling Team’s concept proposes the use of tunnel-boring machines for underground excavation, which can reduce costs and decrease excavation time by 50%.

The team is collaborating with Pacific Northwest National Laboratory and Argonne National Laboratory to identify groundwater sources, as well as produce an economic analysis and cost-benefit analysis of the project.

Nelson Energy delivered a virtual presentation of the project to the Energy, Utility and Environment Conference (EUEC). The team also received an invitation to present at the HYDROVISION Conference in Minneapolis in November.

The team is currently studying the feasibility of employing underground pumped hydroelectric storage in Granite Falls, Minnesota, as well as looking into other possible sites in Minnesota and Wisconsin.

Reducing PSH Excavation Duration, Cost, and Risk

The Kinetic Power Team’s tunnel excavation innovations can reduce PSH construction time, cost, and risk by up to 50%.

The team is moving forward in the area of environmental testing. DOE recently approved their submitted plans outlining the types and locations for core sample testing, as well as the number of samples they would like to collect.

The team provided a spreadsheet analysis tool to Oak Ridge National Laboratory and DOE for their use in developing baseline simulation models.

Participating in preliminary discussions with the Federal Energy Regulatory Commission around the hydropower permitting approval processes has provided the team with much-needed clarity about the timelines and processes associated with securing PSH licenses.

Use-case modeling has been carried out for a 1,000-megawatt (MW) baseload renewable power plant and a load-following, fully dispatchable 1,500-MW renewable power plant, both anchored by PSH.

Additional modeling activities are expected to be carried out to investigate dual-use-case scenarios for PSH. The activity aims to gauge the feasibility of combining monthly energy shifting with day-to-night shifting for solar-rich/wind-poor regions.

Employing Modular, Closed-Loop, Scalable Pumped-Storage Hydropower

The Eldredge-Medina Team of Liberty University’s concept consists of a modular, closed-loop, scalable PSH system with a capacity range of 1–10 megawatts that is adaptable to sites without natural bodies of water.

The team is scouting potential locations in the southwest Virginia region where this technology could be successfully implemented, while continuing to carry out hydrodynamic calculations for their PSH system.

The Eldredge-Medina Team is looking ahead to their upcoming physical testing at the Liberty University School of Engineering.

Continue to check back in through the summer and into the fall as we follow these teams and their progress in accelerating PSH development and reducing commissioning time.

Last Updated May 28, 2025