CoMET Brings Together Collaboration in Composite Materials Manufacturing Research

The Composites Manufacturing Education and Technology (CoMET) Facility contains the equipment and materials to transform design concepts into prototypes, and from prototypes to products. It’s an industrial-scale work space that is designed to give the industry what it needs to lower the cost of wind energy and make composite wind blades more recyclable at the end of their life. Not only is CoMET capable of developing next-generation wind turbine blades, the facility’s resources make it a one-of-a-kind learning space for related industries, such as aerospace and construction.

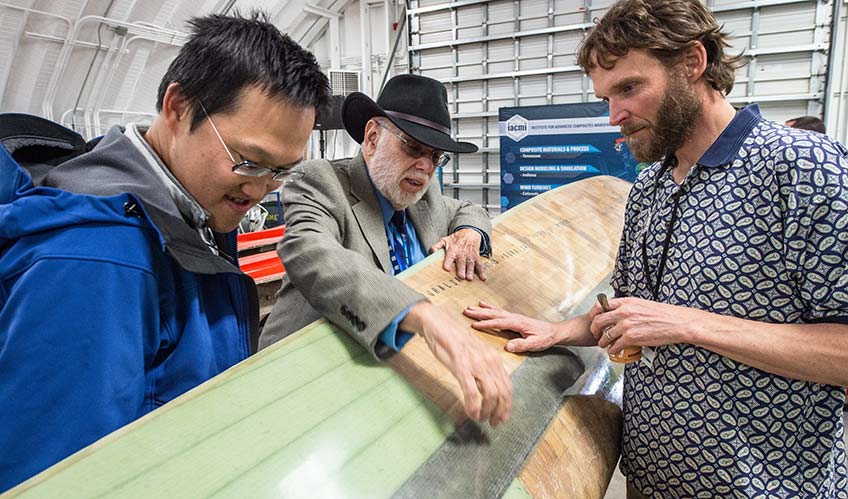

“We wanted a research facility that covered all aspects of wind turbine blade manufacturing, but also brought together the workforce and researchers in composite materials,” said David Snowberg, a senior mechanical engineer at NREL. “CoMET is a unique meeting ground—it gives us a common space to push the boundaries of this field, collaboratively.”

For users of CoMET, Snowberg and colleagues provide assistance as onsite specialists, guiding partners through development and validation. As researchers whose subject matter is at the cutting-edge of turbine design, they’re helping NREL assist the incoming workforce in what’s becoming a highly competitive industry.

The CoMET facility grants users access to 3-D printed blade tooling, composite material mixing equipment, state-of-the-art manufacturing techniques, and novel materials for rapid prototyping. Users can also simulate and model designs and manufacturing methods, and characterize the structural properties of their prototypes. CoMET is also a research center for thermoplastic resins, which could displace other designs as a reusable material option.

Learn more about the facility today, and find out how to partner with NREL.

Last Updated May 28, 2025