NREL Patent Activity Climbed in FY 2022 as Researchers Recognize More Eureka Moments

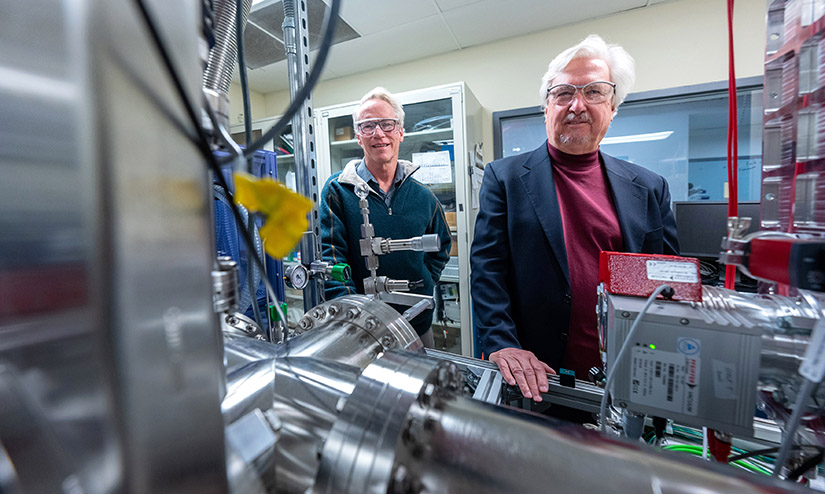

National Renewable Energy Laboratory researchers Mark Nimlos (left) and Robert Baldwin, along with their colleague Kristiina Iisa (not pictured), hold a patent on a process to produce carbon-based materials from bio-oil derived from biomass. Photo by Werner Slocum, NREL

There must be a better way. That thought has sparked more scientific advancements, more eureka moments, more patent applications.

For a quartet of researchers at the National Renewable Energy Laboratory (NREL), the notion of converting woody biomass to an oil that can then be used to produce high-value, carbon-rich coproducts proved to be an environmentally friendly alternative to an intensive mining process. These coproducts include graphite, a vital part of lithium-ion batteries used to power a growing fleet of electric vehicles.

“We were able to isolate some material that looked a lot like mineral graphite, and that’s just led to a whole range of new applications and ideas,” said Mark Nimlos, a group research manager at NREL. “Basically, looking at every place that fossil carbon is used in industry and thinking well, we could replace that with biocarbon. The range of applications is really broad. It goes all the way from really high-tech expensive materials like super pure graphite, which is about $20 a kilogram, all the way down to very inexpensive low-tech things like petroleum coke, which certainly has very low economic value.”

Nimlos and his three co-inventors were awarded a patent on the process in March. Researchers at NREL received another 57 patents during Fiscal Year 2022, an uptick from the 47 awarded the prior year.

The NREL Technology Transfer Office counted 133 records of invention in FY 2022, filed for 176 patent applications both in the United States and internationally, and obtained Department of Energy (DOE) permission to assert copyright to 78 software packages, which included the release of 58 instances of open-source software.

Anne Miller, director of the Technology Transfer Office, said NREL files an average of about 170 patent applications annually and releases roughly 48 open-source software titles. “Protecting intellectual property this way enables us to make it available for licensing, which in turn enables companies to introduce products so that NREL innovations have an impact,” she said.

The process to protect innovations as intellectual property begins with researchers submitting records of invention and software records.

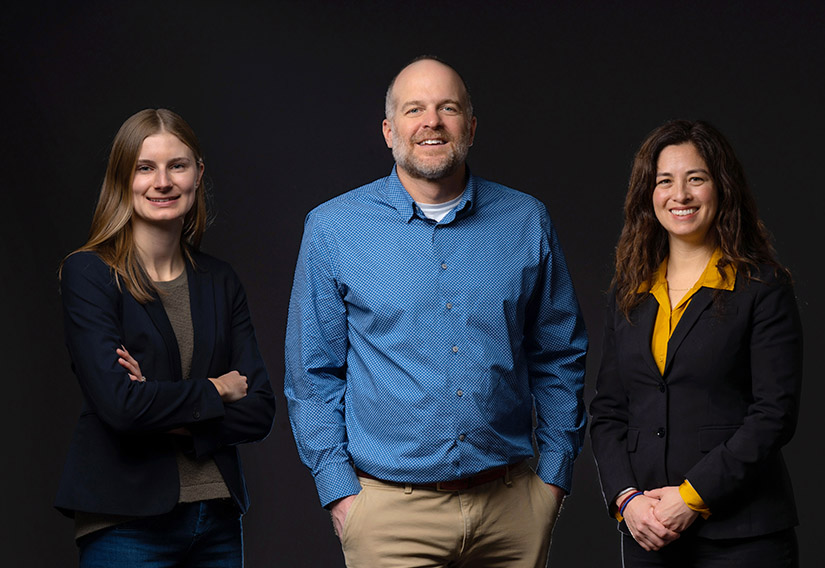

“It's excellent that NREL has a tech transfer office that supports our technology development, that will help us through the patenting process,” said Kim Trenbath, the innovation lead for systems technology R&D in the laboratory’s Building Technologies and Science Center. “Because if we were not working at NREL, and we were kind of working on our own, it would be a lot more challenging for us. They made it very streamlined.”

Trenbath, William Livingood III, Amy LeBar, and Bennett Doherty were awarded a patent in September for technology that allows for greater control of devices plugged in or hardwired into a building. The patent covering “Plug load management system with load identification” enables greater control of plug and process loads (PPLs), which account for 47% of the energy consumed in U.S. commercial buildings.

“These are loads anywhere from the computers, the screens, the elevators, but they're very diverse, and there's really not a great way of controlling any of them really, because they're very occupant dependent,” said Trenbath, whose work was funded by the DOE Building Technologies Office. “There's a huge need to identify some solutions that take advantage of emerging technologies in this area for controlling PPLs in a building.”

Controlling the load means being able to shut off equipment when not in use, such as in the middle of the night. The initial idea paired smart outlets that could tell what was plugged in using a Radio Frequency Identification (RFID) tag attached to each device. The communication between plug and device also allowed for the collection of data about how much power was being used. Then the researchers thought, there must be a better way. They flipped the orientation around and used RFID tags in the plug faceplates instead. Smart devices could then be plugged in, with the controls associated with the devices rather than the outlets. No matter where in the building a device is plugged in, the control system can take the appropriate action.

“The moment they told me that I thought, ‘Oh, wow, that's clever. Why didn't I think of that?’” said Livingood, group manager of commercial buildings research. “Flipping the orientation makes retrofit so much easier, because now rather than digging into electrical circuits and putting in a smart receptacle that requires an electrician in all cases, you're just replacing the faceplate and then embedding the RFID reading mechanism into devices, which have an intrinsically faster product refresh rate.”

The researchers dubbed the plug load management system ATLIS, for Automatic Type and Location Identification System.

“There are other solutions,” Trenbath said. “For example, you could go through your office and unplug everything and shut everything down. That doesn't happen.”

Sand Could Be Storage Answer

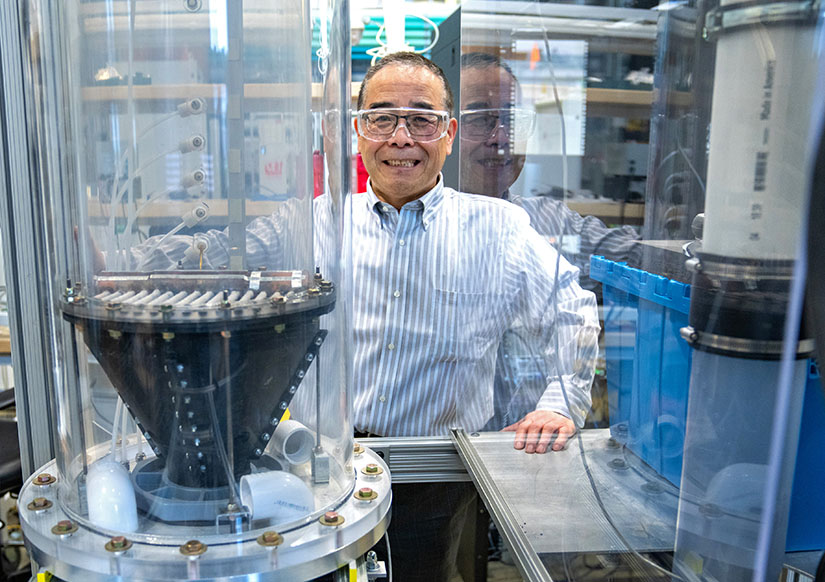

For Zhiwen Ma, a researcher in the Thermal Sciences Group, developing a new way to store energy for tens or even hundreds of hours has yielded four patents to date with the most recent awarded in October. Another two patents are pending. His solution offers a path toward decarbonization.

“Decarbonization is a big ask and has big hurdles. Mainly you need to compete with natural gas, which is cheap, convenient, and easy to use because you’re just turning a valve,” Ma said. “There’s nothing more convenient than that. Therefore, energy storage for this decarbonization needs to beat natural gas, and beating natural gas means that you must have low-cost energy storage and also needs to be very versatile and also be able to integrate with renewable energy.”

Zhiwen Ma displays his device that recently received a patent for solid-particle energy storage. The device uses heated silica sand as a way to store energy for later use. Photo by Werner Slocum, NREL

Instead of heating buildings with natural gas, Ma recommends using a high-quality sand superheated to more than 2,000 degrees Fahrenheit. Once heated, the sand stores energy for use later. Ma’s latest patent, “Methods and systems for thermal energy storage and their use in buildings applications,” calls for the particles of high-quality silica to be heated during off-peak times, when electricity demand and costs are relatively low, and for the stored energy to be used during peak periods when the demand and cost is higher.

The heated sand, which Ma said can be sourced from the Midwest, is stored in concrete silos. The more silos, the greater the amount of energy storage. The same silos can be used to store the chilled particles, therefore cutting the storage containment cost nearly in half by not having separate systems.

“That expands the function of energy storage to be more competitive than ice storage, which is the current technology,” Ma said. “Our technology can serve all four seasons. It's not just summertime like with ice, but it also can supply heat in the wintertime, so it has more of a use factor.”

Ma said using heated sand as an energy storage medium has advantages over batteries. While portable, batteries are most effective for short-term storage. DOE’s Advanced Research Projects Agency–Energy (ARPA-E), which invests in high-risk technologies that have the potential to reduce the cost of energy, has financed the research.

Flexibility Plays Role in Offshore Wind

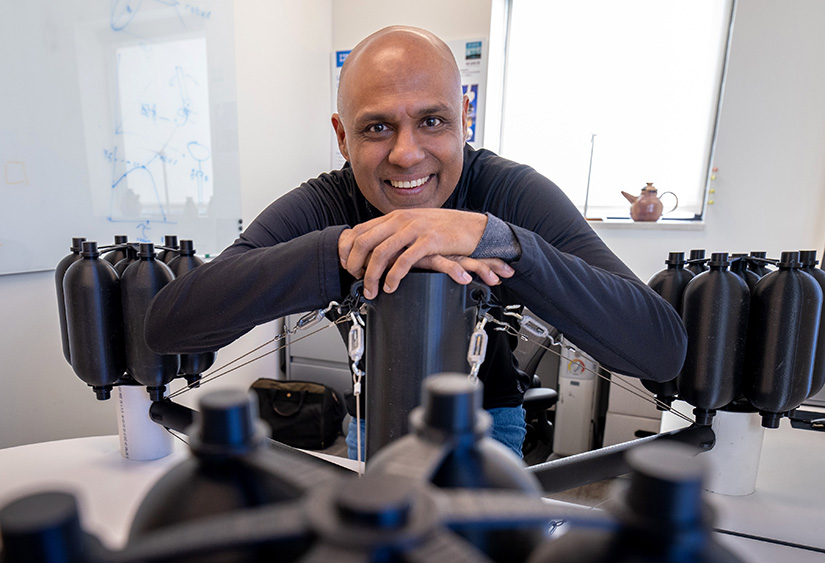

Senu Sirnivas took what he learned during 20 years spent in the offshore oil and gas industry in a different direction. Now working on producing power from wind, Sirnivas helped design a way to protect floating turbines from being battered by ocean waves. Brainstorming with colleagues Rick Damiani, and Fabian Wendt led to the idea of a platform capable of riding out the rough spots. They were awarded a patent in October for their “Flexible aquatic substructures.”

Anything in the ocean is affected by movement of waves. Those waves rock a platform back and forth and heave it up and down. That means a wind turbine on such a platform would be less efficient producing energy as it gets buffeted by the waves. The newly patented design covers a fiberglass/concrete structure kept afloat by a series of fiberglass buoyant tanks and concrete legs that can pivot, which mitigate some of the overall platform movement from the waves.

The device known as Ultraflexible Smart Floating Offshore Wind Turbine (USFLOWT) can be manufactured, assembled on-site and precommissioned, then towed to where it needs to be installed.

“Offshore systems in general cost more than land-based systems, and it does not come cheap,” Sirnivas said. “What you must do in order to convince the offshore windfarm developers is to de-risk the technology, which is ongoing, but we're not there yet. Once the technology is de-risked, shown structurally reliable, and economically viable, we can engage with the windfarm developers. They're definitely knocking on the door and wanting to know more about the technology, which shows their investment interest in the future.”

The project has received funding from ARPA-E. The last $1.5 million enabled the NREL team to evolve the 10-megawatt floating turbine design, which started with internal funds, then continued with Energy I-Corps and then Technology Commercialization Fund. An additional $5 million in ARPA-E funds will go toward testing the system in a sub-scale version in a wave basin to further evolve and de-risk the technology.

“ARPA-E is funding moonshot projects,” Sirnivas said. “They are not funding low-risk readily achievable projects. So, if you look at it from that standpoint, this is a high-risk/high-reward project.”

Sirnivas showed off a model of the device at the ARPA-E Energy Innovation Summit held in Colorado last summer. The display caught the attention of Secretary of Energy Jennifer Granholm, who stopped to inspect it and ask questions. “I had 10 minutes with the secretary explaining the system, and she was excited,” he said. “She was thrilled with the prospect of an innovative offshore floating wind technology being developed at NREL to help combat climate change.”

Machine Learning Tool Has Answers

Nolan Wilson knew there was a better way to determine how polymers made from biomass could replace plastics made from fossil fuels. He just had to come up with it. The solution developed alongside Peter St. John and others at NREL is PolyID, a free tool that relies upon machine learning to find the answer.

PolyID, a software written in Python, will be expanded to a web-based version soon. The tool dramatically reduces the amount of time researchers must spend to determine if a bio-based material can be put to a particular use.

“Biomass can give us a whole bunch of monomers that we can turn into polymers,” said Wilson, a chemical engineer. “It’s this really diverse and amazing set of building blocks for the materials of tomorrow. The challenge is that there are literally millions—tens of millions—of different ways you can combine these building blocks to make new materials and the experimentalists don’t know which ones to try.”

Rather than the many months it may take for an experiment to determine the suitability of a bio-based material for a particular use, the artificial intelligence built into PolyID can provide the answer in seconds. The tool looks at the chemical structure and predicts material performance.

“We built it because we really needed something that was fast—faster than anything that existed—and more accurate and really built for bio-based materials,” Wilson said. “There are tools that are predictive for petroleum-based feedstocks and they’re not really designed for our bio-based feedstocks. We had to think about how do we build a new tool that will be useful for our purposes.”

PolyID will also allow researchers to tell what a second use for a recycled material could be.

To validate PolyID, researchers experimentally synthesized 22 polymers.

“What's great about NREL is that I can pass this off to somebody who can actually make the material, and that's unique,” Wilson said. “We're an applied lab. We're here to build new things. This isn’t just a computational tool. It's an instrument of discovering tomorrow's next greatest materials.”

The DOE Bioenergy Technologies Office funded the project.

Bio-Oil Process Eliminates Need To Dig

Wilson along with Nimlos, Robert Baldwin, and Kristiina Iisa holds a patent on “Valorization of bio-oils,” covering the methods used to make coke, graphite, graphene, and other carbon-based materials from bio-oil derived from biomass. Baldwin, a principal scientist, said many researchers have experimented with the uses for biomass, “but nobody had considered using bio-oil to make bio-based carbon. The idea for using the heavy-ends of bio-oil to produce high-quality carbon is where the novelty came in.”

Producing graphite from bio-oil solves a supply chain issue; the vast majority of the mineral is mined in China. The process is environmentally unfriendly with a very large carbon footprint.

In latching onto this novel idea, Baldwin thought back to his prior research with bio-oil a decade ago. He learned then that an application of what’s known as hot-gas filtration substantially improves the properties of a bio-oil. The process yielded a material that had basically no mineral content; the minerals represent imperfections in the material.

“By applying hot-gas filtration to the bio-oil vapor we could produce a product that contained essentially zero ash,” Baldwin said, “and that kind of stuck with me.”

That idea eventually led them to producing graphite and other forms of carbon from the bio-oil.

“Mineral graphite has a lot of contaminants that you have to get out,” Baldwin said. “That generally requires use of strong acids. That’s on top of the mining operation, which is in and of itself environmentally nasty. You're piling on all of this really awful chemistry to basically get the purity that is required for the final product. Use of hot-gas filtration along with pyrolysis allows us to produce a precursor for bio-based carbon that is mineral-free.”

The Bioenergy Technologies Office-funded process produces a product different than biochar, which is a carbonaceous residue containing significant mineral content that must be removed if the carbon is valorized for use in batteries and other high-end applications.

“A lot of the minerals in the original biomass wind up in the biochar, so if you want to try to make a high-quality carbon out of biochar, you're faced with the sort of the same dilemma that you have using mineral graphite,” Baldwin said. “You have to work really hard to get all those minerals out in order to upgrade the quality so you can use it to make graphite, but a lot of people are doing that. A lot of people think that's the right way to go. We just took a different path, a different approach.”

Nimlos said a preliminary techno-economic analysis of their process indicates “we can at least be competitive with existing costs of graphite and perhaps be less expensive.”

Learn more about the NREL-developed technologies available for licensing.

Last Updated May 28, 2025