Lightening Soldiers' Loads by Lifting PV Cells onto Flexible Surfaces

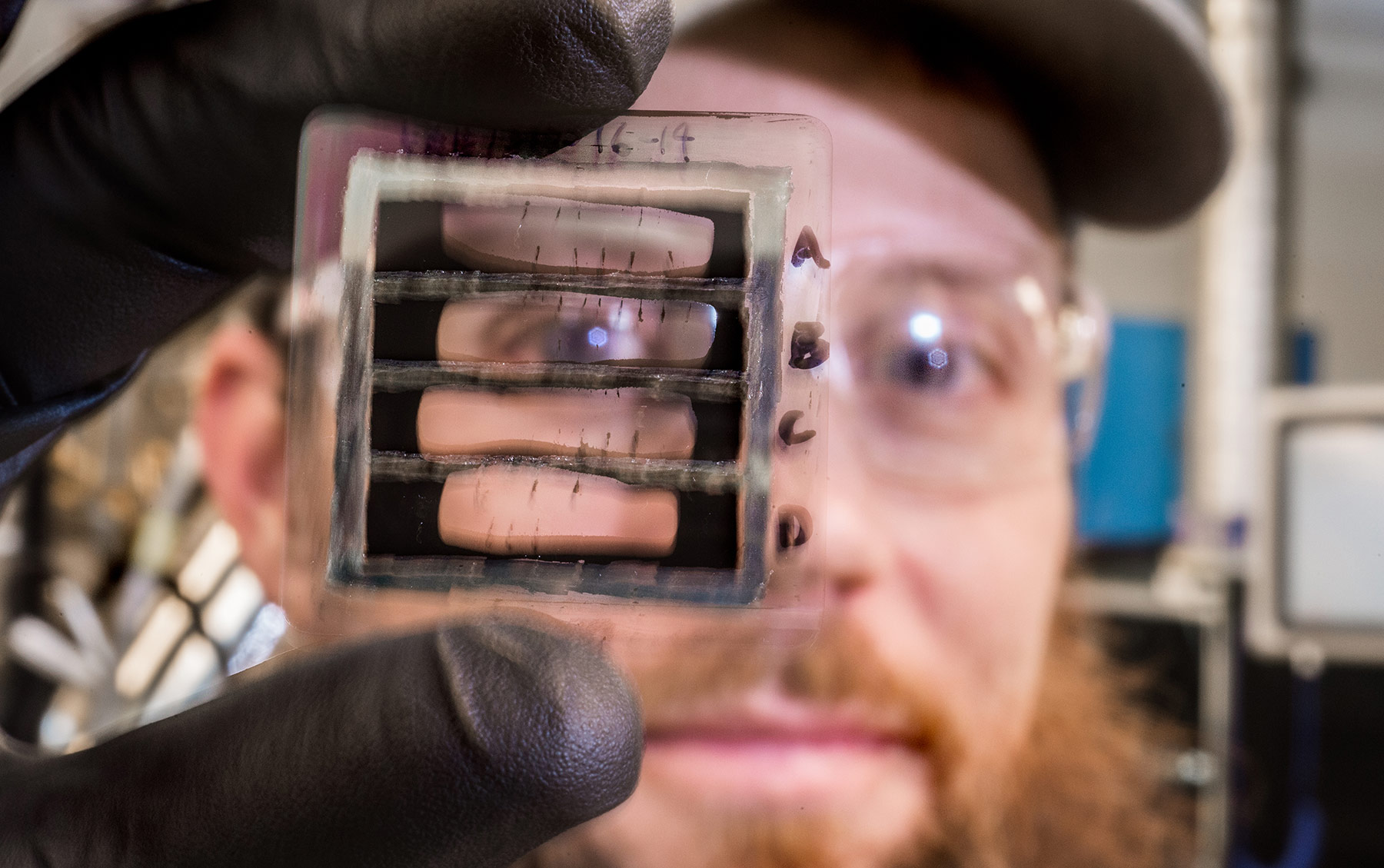

NREL scientist Matt Reese holds a substrate with the solar cells removed to minimize the weight of the solar cell. Photo by Dennis Schroeder/NREL 40800

Two thousand years ago, Roman legionnaires lugged 100-pound packs into battle. A lot has changed since then, but technology hasn't really reduced an infantryman's load. On the battlefield, mobility is critical—but a typical, modern Marine may shoulder an 80-pound backpack containing 20 pounds of back-up batteries for an array of electronics.

When soldiers or supply convoys are forced to move slowly on repeated trips, they can become "targets of choice" for enemy combatants. Because of this, the Energy Department and Department of Defense are looking for ways to ease such heavy burdens, and a team of researchers at the National Renewable Energy Laboratory (NREL) is exploring novel approaches for making renewable power sources lighter.

Photovoltaic (PV) cells are the military's choice to power remote bases, but the ones it uses are not only large and inflexible, they aren't very efficient. Last summer, NREL embarked on a $1.5 million, three-year research and development contract with the Office of Naval Research to explore making lightweight solar cells. In this work, the journey has been marked by fundamental science—and creative thinking.

"What if we could grow solar cells on the same heavy substrate we use in the standard high-efficiency, low-cost polycrystalline processes?" asked Matthew Reese, an NREL staff scientist in PV research. Afterwards, researchers could transfer the high-efficiency cadmium telluride (CdTe) or copper indium gallium selenide cells to lighter-weight packaging—trimming the weight of the cells.

Thin-film solar cells, grown on substrates such as stainless steel, titanium foils, and polyimide, produce flexible products that are ideal for solar blankets and tarps. As such, the thin films are more portable—but they also typically lack the higher efficiency of cells grown on thick-glass substrates. Reese's challenge has been to combine the best of both.

The solution: a novel "lift-off" of a high-efficiency cell that could then be repackaged on thin film.

Marine officer Brandon Newell worked with renewable energy sources such as solar panels in Afghanistan. Photo by Brandon Newell

The seed of this idea began around four years ago, when Reese was working with NREL's Teresa Barnes on a research project funded by the Energy Department's Foundational Program to Advance Cell Efficiency (F-PACE). F-PACE supports PV cell efficiency, and the NREL team was making lightweight CdTe solar cells on flexible glass.

"When you grow a CdTe cell, you need to grow it for highest efficiency on a transparent substrate," Reese said. In turn, "the order in which you grow the layers of a cell is critical. For CdTe, the substrate has to be transparent, and that limits choices" because CdTe requires high temperatures. Plastics, therefore, won't work.

Although growing CdTe cells on glass, which can withstand high temperatures, was promising, this approach had a drawback. Even flexible glass can shatter, making it unreliable for certain military applications. But researchers felt that retreating to low-efficiency, flexible cells wasn't an option. The military is interested in high specific power, which means it wants as many watts as it can get out of the minimum amount of weight. To hit that goal, many researchers think of using III-V multijunction solar cells, the most-efficient PV materials. "But those cells are too expensive," Reese said. "Even the military can't afford that option."

Global Solar's lightweight, flexible, and portable power pack is an example of solar in the field; these thin film portable power packs have been field tested by the military. Photo by Global Solar Energy

The Navy Sees a Need

When work finished about a year ago on the F-PACE efficiency project, Reese and his colleagues continued to think about ways to combine high-efficiency PV with robust packaging that was lightweight. After gaining support from NREL through a Fiscal Year 2016 Laboratory Directed Research and Development project headed by scientist Miguel Contreras, the team wrote a follow-up white paper. The project drew interest from the Office of Naval Research—but the Navy wasn't looking for a packaging makeover. Project leaders wanted an approach with the highest efficiency, and therefore, with high specific power.

"We thought for a little bit, and then it occurred to me. We'd done this diagnostic test by delaminating CdTe cells," Reese said, referring to a way of lifting a cell off a substrate to remove it. "Maybe we really could have the best of both worlds." Researchers could do all of the standard higher-temperature processing on the rigid glass substrate, which they know how to process—then they could delaminate the high-efficiency cells and put them in any package. "We could de-couple growth constraints from a package of choice. You could select whatever you wanted as the ideal package at the end," Reese said. This concept was approved, and the project for the Navy began in August.

To launch the exploration, Reese got creative. "I like arts and crafts," he joked.

While there are a variety of ways—excluding razor blades—to remove cells that are a few micrometers thick, Reese and his team chose a method that uses liquid nitrogen. Once that step was completed, they used a "handle" that attaches to the cell, allowing them to put the cell on a flexible substrate. The team managed to demonstrate clean separation on small areas as part of the initial tests. That showed promise, but there's more work to be done.

Reese and his team are optimistic—the idea of transferring these low-cost, high-efficiency solar cells to the types of flexible backings that could withstand field exposure is encouraging.

"There are a series of different ways we can try to do this," he said. "We are investigating several approaches in parallel. We want to understand what needs to be controlled. What are the knobs we can turn to separate large area samples cleanly at a specific interface? How do we control fracturing in polycrystalline systems? What are the inherent limits to its flexibility?"

If successful, the flexible, lightweight, high-efficiency, and reliable solar power will not only reduce the weight that a soldier needs to shoulder—it could also maximize military operational effectiveness in unmanned aerial vehicles and reduce the number of manned supply convoys. In other words, if this works, the NREL team could ultimately help the military ease burdens and save lives.

Learn more about NREL's solar research.

— Connie Komomua and Ernie Tucker

Major Brandon Newell: Marine Experience Fuels Passion for Renewables

Marine Major Brandon Newell at the National Renewable Energy Laboratory as its first military fellow, looking for ways to leverage the laboratory's research for the military. Photo by Ernie Tucker/NREL

Brandon Newell had been in the Marine Corps only 18 months in 2003 when he found himself on the Kuwait-Iraq border as the United States launched Operation Iraqi Freedom. He saw, firsthand, the difficulty of battlefield logistics and how a lack of efficiency could impact a mission.

"Speed is something the Marines try to achieve," he explained, because the Corps' capabilities are based on agility and mobility.

During those initial days of the Iraq War, there was added urgency because nobody knew whether Saddam Hussein's forces would deploy chemical weapons. The marines were heading from the Kuwaiti border to Baghdad, moving farther and faster than they had ever pushed.

About two weeks into the battle, something unexpected happened. As his unit was setting up communications equipment, they saw armored U.S. vehicles rolling past them toward the rear. "This was odd, because up to this point, everyone was moving north towards Baghdad. About an hour later, we got a call for an operational pause, because we'd outrun our logistics," he said.

Vital supplies such as food, fuel, and batteries couldn't keep up with the attack—so the troops had to pull back and wait for fresh materiel to catch up. "We had stretched lines so thin that we had to take a break from the war," he said. "This actually led the Marine Corps to completely reorganize logistics support. We're better now, but we want to improve more."

That's the motivation Newell brought to NREL in July when he started a one-year term as the National Renewable Energy Laboratory's (NREL's) first military fellow. He wants to help Energy Department efforts in support of the Department of Defense (DOD) and to explore NREL capacities that might benefit the military. But for Newell, who now holds the rank of major, his interest in renewable energy—and NREL—is not new.

A Curiosity about Renewables and NREL

Newell had been intrigued with solar energy since sixth grade when he built a model solar car—and throughout his career, thoughts about renewables remained. For example, while stationed in Kaneohe Bay, Hawaii, for three years starting in 2005, he saw plenty of renewable energy technologies.

Eventually, in 2009, after he connected with John Barnett in NREL's Integrated Applications Center, Newell spent six weeks as what is believed to be NREL's first active-duty military intern. During that time, he and Barnett co-authored a white paper for the Office of the Secretary of Defense, recommending a military liaison officer at NREL and making the internship a regular thing. It was August—just as his NREL stint was ending—and the timing was perfect.

Newell attended the first Marine Energy Summit in Washington, D.C.—a one-day event held then to address the topic of energy, water, and waste on the battlefield. Noting his interest, the Commandant picked him to be part of the Marine Energy Assessment Team, which was deploying to Afghanistan. "I was thrilled. I was actually being given the opportunity to apply what I had been learning to helping Marines on the battlefield," Newell said.

Newell arrived in the Helmand Province of southwest Afghanistan in September 2009 as part of a six-member team, which also included Barnett. Several weeks there allowed Newell to see some of the hardships—but also the potential for renewable energy and energy efficiency alternatives to lighten the 80-100 pound load infantrymen typically carry.

After returning from that fact-finding mission, he helped brief the Pentagon on keeping the foot-mobile Marines agile—and the Marines leveraged his expertise. For example, in 2011, he deployed again to Afghanistan, serving as energy liaison officer to the regional command.

Benefits of Renewables for the Military

Newell's various experiences help him advocate for advances in military capabilities. He wants to assist as the Marines explore variety of technologies to keep them efficient. Newell said he will attempt to translate the realm of the possible by "leveraging the capabilities at NREL for our needs in the military." He admits such a task isn't always easy, but it should help to "have someone who has been on both sides to help imagine what's possible." Furthermore, he'll be looking at technologies that the military is not yet trying, and exploring capabilities within NREL that DOD may not be aware of.

Even after he leaves NREL, knowing he may not return to energy assignments, he expects the investigations in renewable energy technologies will continue—and lessons he's learned on both battlefields and in laboratories will make a difference to future Marine leaders and others in the service of the United States.

Last Updated May 28, 2025