Can New Synthetic Fuels Propel Commercial Aircraft?

National Laboratory of the Rockies’ Computational Models Help Researchers Evaluate Aviation Fuel Performance To Clear the Runway for Physical Testing

Whether by plane, train, or automobile, your mode of transportation needs a power source to get you to your destination. When it comes to cars and planes, that usually means petroleum-based fuels like gasoline, diesel, or jet fuel. For decades, aviation fuel has remained largely unchanged in its chemical composition.

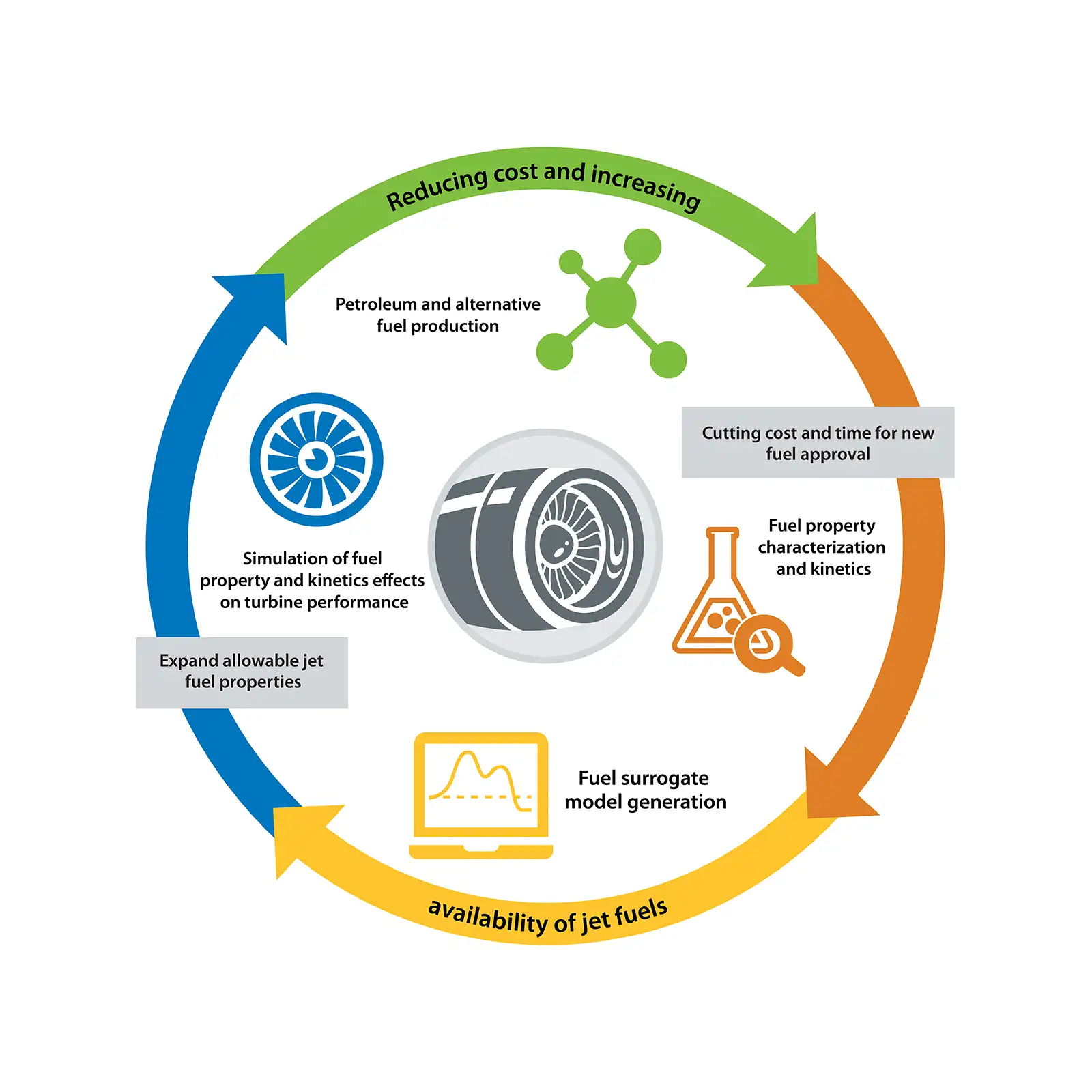

Now, advancements in computational modeling at the National Laboratory of the Rockies (NLR) are helping to speed up the production process for new synthetic fuels in the United States to enable a more ready supply of aviation fuels. Streamlining process improvements around getting new aviation fuels approved for commercial use de-risks investments, equating to years of time and millions of dollars saved.

NLR’s High-Flying Computing Capabilities

Adequately testing new synthetic fuels traditionally has required thousands of gallons of fuel to be produced for use in a lab-scale combustor. New fuels, however, are often only developed liters or milliliters at a time. Scaling up production of those fuels can be both too expensive and time consuming for many potential producers.

That is where NLR’s capabilities in computational modeling could mean the difference between an idea for a new fuel and a fuel that takes flight.

NLR is host to one of the most advanced supercomputers in the country, called Kestrel, which can be used by researchers in collaboration with the U.S. Department of Energy’s Office of Critical Minerals and Energy Innovation. While Kestrel provides the computational infrastructure to conduct a variety of large-scale computational analyses, NLR researchers also develop a wide array of applied math and computational techniques that can be shared with the broader public.

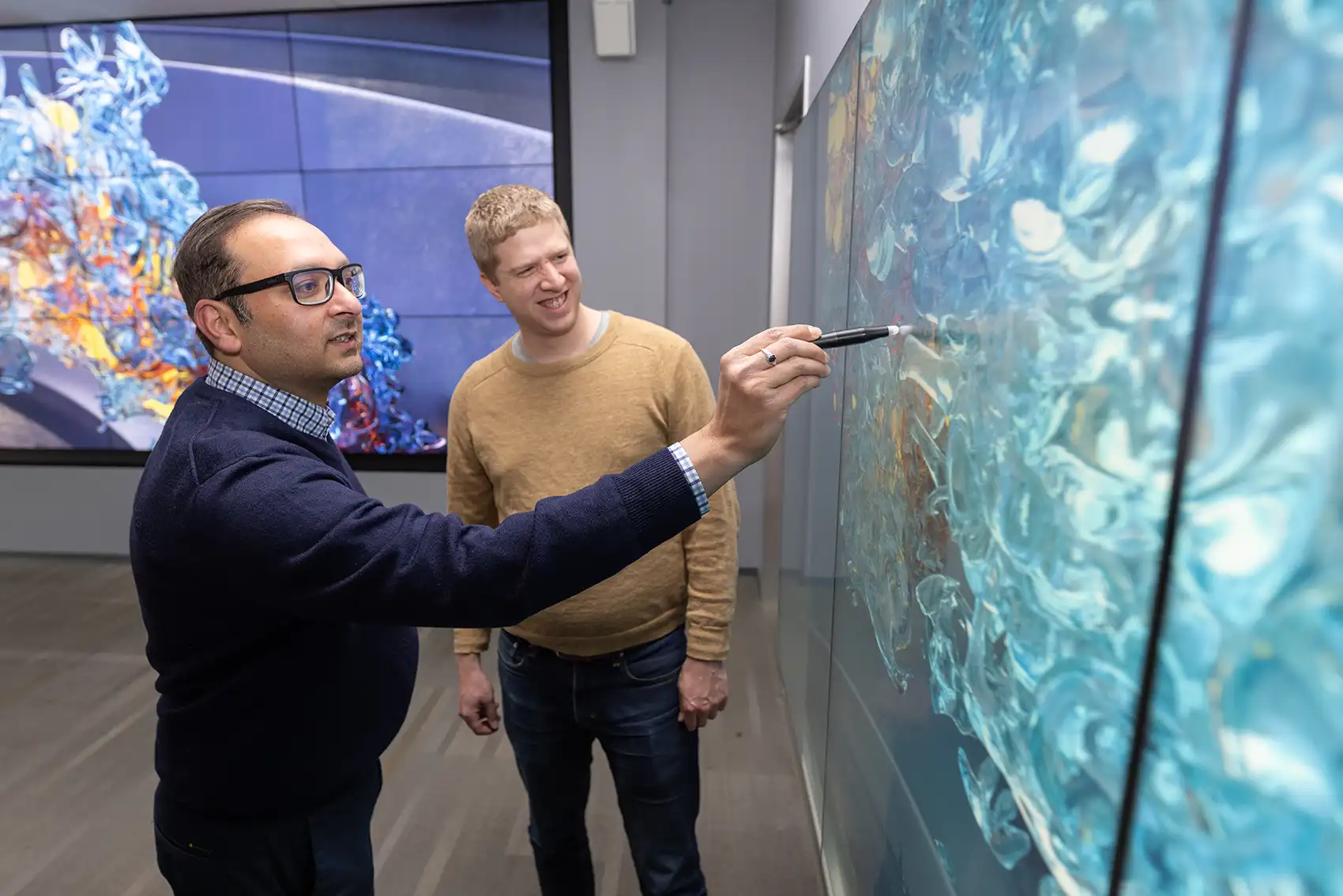

Research engineers like Shashank Yellapantula take those techniques and apply them to spaces like synthetic jet fuel development by creating and refining computational models to reveal how the properties of potential new fuel components and mixtures affect their viability before they are put into production. This is important because the hydrocarbon composition of the fuel influences properties such as density, viscosity, and vapor pressure, all of which play into fuel performance and compatibility with current jet engines.

“Specifically, we are looking at how we can increase the availability of these fuels in the market and how can we increase the total volume of synthetic jet fuels being used right now in commercial aviation,” Yellapantula said.

Yellapantula and his research team are developing tools to simulate whether new fuels should be brought to the physical testing stage. They test the chemical properties of potential synthetic jet fuels by using numerical simulations, which drastically reduces the cost needed to clear them for commercial production.

“In this way, we’re avoiding burning a lot of potential fuels before they are ready for field performance testing,” he said.

Clearing New Fuels for Takeoff

“There are a number of bottlenecks in the synthetic fuel production process,” Yellapantula said. “One is that you need to produce large amounts of new fuel to test it, and another is getting that fuel qualified through the ASTM International.”

ASTM International sets global jet fuel standards to ensure fuel producers meet certain safety and performance criteria, so that, regardless of how it is made, the new fuel can be used in jet engines everywhere. The goal is to develop fuel that can be used as a “drop-in” substitute for petroleum-based jet fuels, such that current jet engines would not need to be modified to use them. But factors like high production cost, limited feedstock availability, and lack of compliance guidelines can all cause bottlenecks in the process to develop new synthetic aviation fuels.

The latest tool in NLR’s computational kit is FuelLib: an open-source database of jet fuel property predictions designed to help researchers and producers alike estimate the properties that make safe and reliable synthetic fuel compounds.

The Fleet of SAF Analysis Tools

To understand Yellapantula’s work and how his team developed FuelLib, it is important to first understand NLR’s world-class Pele suite.

Importantly, the Pele suite encompasses tools that simulate a variety of combustion applications to determine how different fuel properties affect turbine performance. It leverages NLR’s capabilities in both high-performance computing and machine learning to simulate how both conventional jet fuels and synthetic jet fuels combust based on current turbine specifications.

FuelLib provides a springboard for that research.

“We’re developing these modeling tools to help researchers, engine manufacturers, or field producers, from small fuel and energy startups to large companies like Exxon or Shell,” Yellapantula said. “Our tools give them a very good indication of how a certain fuel would behave in the environments in which actual aircraft engine combustors function.”

Yellapantula has worked closely on the development of tools within the Pele suite with NLR Computational Scientist David Montgomery. Montgomery led the development of FuelLib by building on previous models that were based on Stanford University research.

The FuelLib library is a collection of conventional and synthetic jet fuels characterized by hydrocarbon composition using gas chromatography. Its users can predict thermodynamic properties of any fuel component or mixture in the library and even add new fuels to it by uploading the fuel’s hydrocarbon composition and its group decomposition.

FuelLib and the other tools NLR has developed to analyze synthetic jet fuels enable researchers like Montgomery and Yellapantula to more easily categorize the properties of synthetic jet fuels, much in the same way that you would see different octane levels on the gas pump when you fill up your car’s gas tank.

“Jet fuels are made up of hundreds to thousands of different hydrocarbon compounds, and we don't know exactly which ones are in each fuel,” Montgomery said. “However, through gas chromatography analysis we have a sense of typical compounds for each hydrocarbon family and carbon number. We can utilize this information along with tools like FuelLib to help us rapidly predict the thermodynamic properties of fuels and potential variants.”

The properties each compound has could impact the fuel’s performance in a variety of ways, particularly in thermodynamics, which in turn, could affect its compatibility with current jet engine designs.

Computing a Destination

Montgomery is now working to fully integrate FuelLib into NLR’s larger host of analysis tools. Both FuelLib and the Pele suite of tools are open source, meaning they are readily and easily accessible, which enhances their ability to expand through the contributions of users outside of NLR, including other laboratories, universities, and synthetic jet fuel producers, and adapt to their needs.

“FuelLib is available right now on GitHub through NLR, and anyone who wants to use it can download it for free,” Montgomery said. “If a user wants to add to the tool, they can submit a request, which is then thoroughly tested and reviewed by a team here at NLR to ensure accuracy and seamless integration with the existing code base.”

Yellapantula and Montgomery’s work is designed to be a part of a larger open-source modeling framework for synthetic jet fuel development. By integrating FuelLib with the larger framework, they hope to provide a platform for users of all experience levels and backgrounds in the fuel industry to spur production of new fuels within the United States.

“A synthetic fuel produced within the U.S. is not typically bound by all the price fluctuations that you see in the international petroleum market, so it can provide a more reliable feedstock option for aviation fuels,” Yellapantula said. “We want FuelLib and our suite of analysis tools to play a critical role in certifying new fuels, increasing the volume of synthetic fuels that are available in the commercial aviation market in the U.S. and bolstering energy security here at home.”

Learn about NLR’s computational science research and download the FuelLib data. Additionally, discover NLR’s aviation and broader transportation and mobility research.

Last Updated Jan. 22, 2026