Turning Plastic Waste Into Opportunity: Ongoing Projects Demonstrate Broad Applications of Chemical Oxidation Recycling Platform

Industry and Research Partnerships Accelerate Commercial Adoption and Scale-Up

The chemical oxidation recycling platform, originally developed through the U.S. Department of Energy’s (DOE’s) BOTTLE Consortium, offers a practical, cost-effective, and scalable solution for processing contaminated, mixed, and multilayer plastic waste.

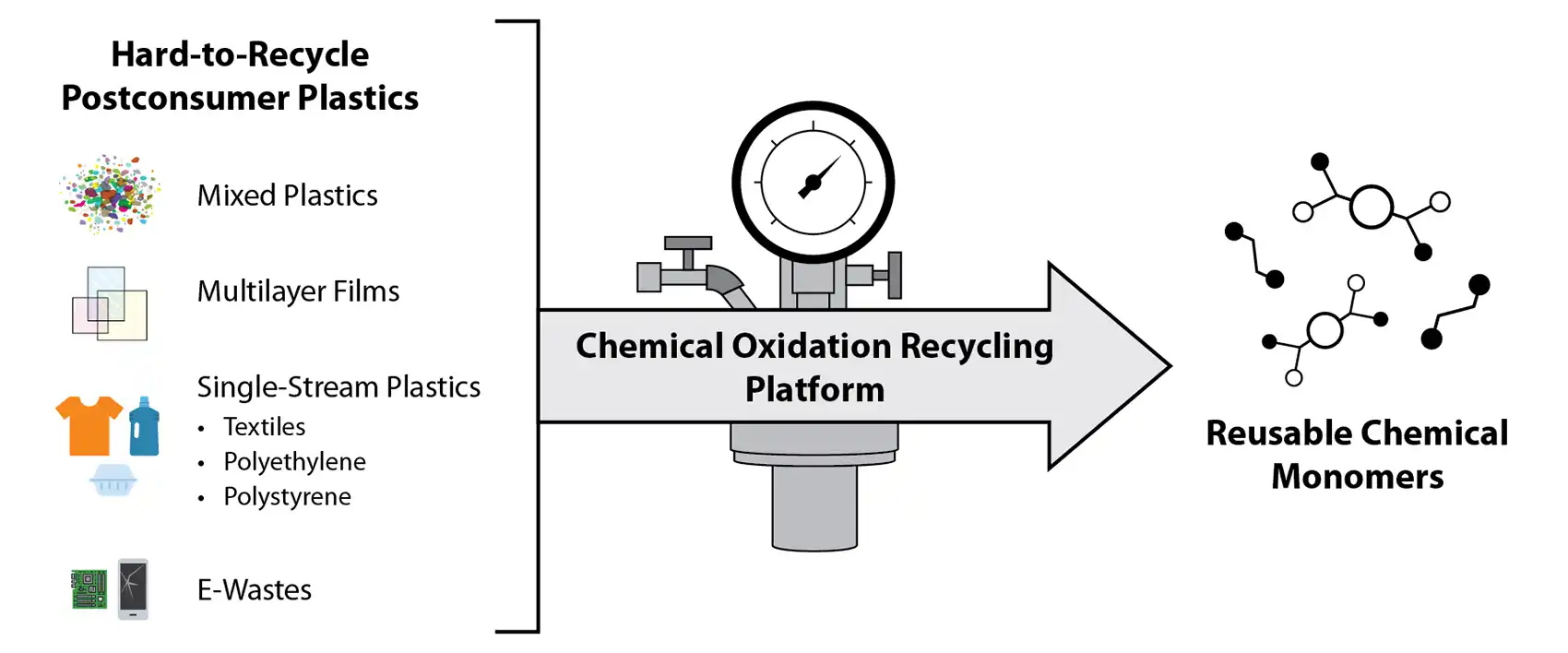

This innovative platform rapidly breaks down hard-to-recycle plastics into valuable chemical building blocks and is already demonstrating its effectiveness through four ongoing research projects targeting complex waste streams.

R&D Magazine named the platform a 2025 R&D100 Award finalist, recognizing it as one of the year’s top innovations with significant potential for impact and advancement in the field.

“This is a promising technology with potential for handling plastic waste streams that are hard to recycle today,” said Gregg Beckham, a senior research fellow at the National Laboratory of the Rockies (NLR), formerly known as NREL, and CEO of the BOTTLE Consortium. “We're now taking a closer look at its economics, applicability, and scalability across a variety of applications.”

Four Projects Ready the Technology for Specific Market Sectors

First introduced in a 2022 Science article, the platform has since led to four foundational patent applications and is now progressing toward broader commercial adoption through four industry-aligned projects:

- Polyester Textile Recycling – Converting postconsumer polyester clothing into virgin-quality clothing materials, even when textiles include dyes, spandex, or other additives.

- Polyethylene-to-Surfactant Conversion – Transforming polyethylene, the most common plastic in the United States, into dicarboxylic acids used in surfactants for high-demand detergents and household products.

- Polystyrene Upgrading via Synthetic Biology – Pairing chemical oxidation with engineered microbes to convert polystyrene into a single, high-value product such as muconic acid, a precursor to nylon and other performance-advantaged materials.

- Multilayer Film Recycling – Deconstructing flexible, layered films commonly used in consumer packaging, separating useful polymers from adhesives, foils, and other additives.

Addressing the Complexity of Real-World Plastic Waste

As global plastic production continues to increase, industry seeks innovative recycling systems that can manage the complexity and contamination of real-world plastic waste streams. Most current recycling technologies require pure, sorted inputs and are unable to handle additives, layered materials, or mixed polymers.

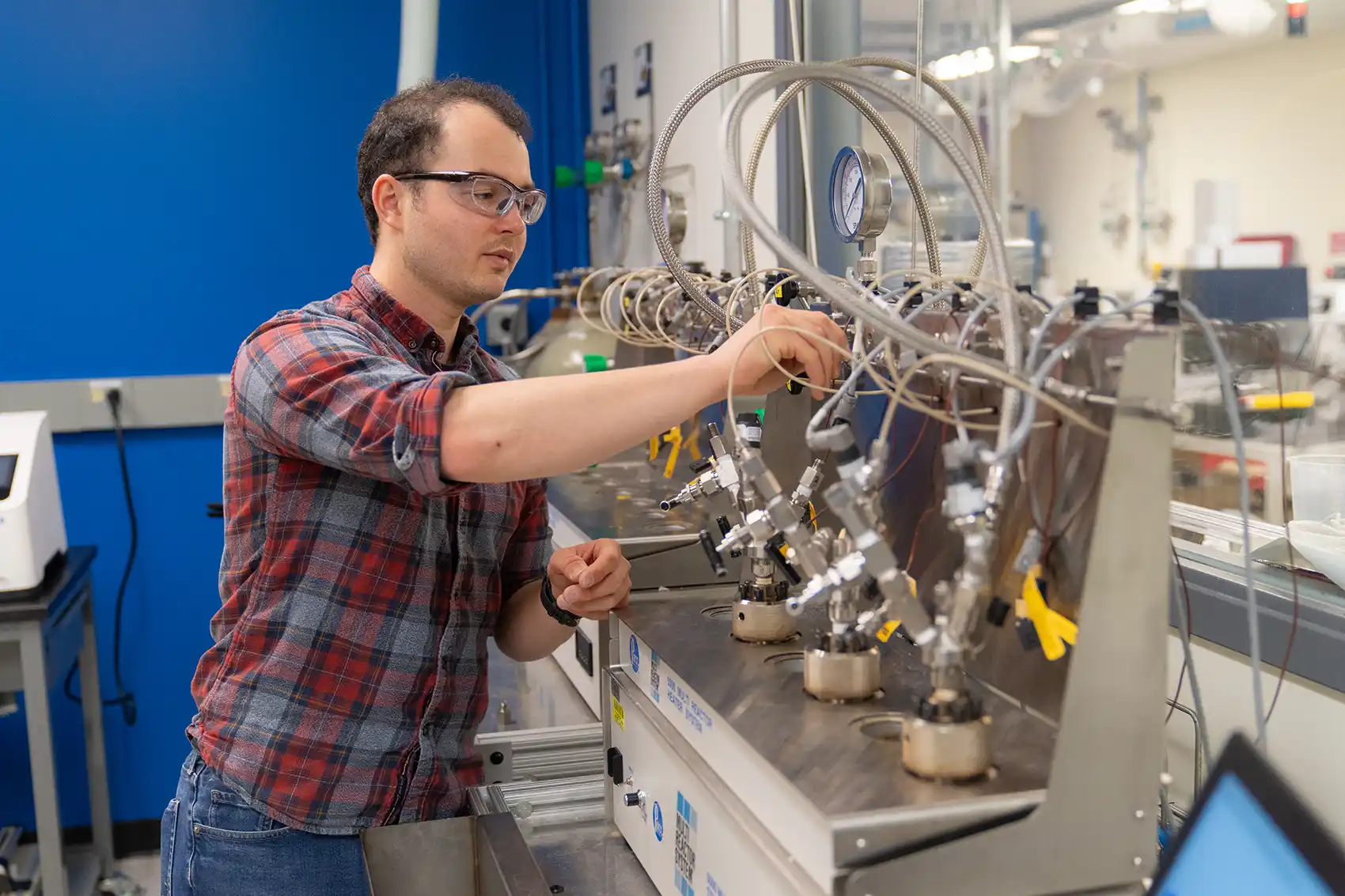

Developed by the NLR-led BOTTLE (Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment) Consortium, the platform addresses these challenges. It uses oxygen, heat, solvent, and widely available catalysts to deconstruct postconsumer plastic waste—even when contaminated or structurally complex—and recover high-value chemical feedstocks. This compares to other recycling technologies that are sensitive to impurities and cross-contamination, often requiring additional sorting or preprocessing steps.

The BOTTLE Consortium is supported by DOE’s Bioenergy Technologies Office and Advanced Materials and Manufacturing Technologies Office. It comprises a variety of national laboratories and academic institutions, including NLR, Oak Ridge National Laboratory, Argonne National Laboratory, SLAC National Accelerator Laboratory, the Massachusetts Institute of Technology, the University of Wisconsin–Madison, Colorado State University, Northwestern University, and the University of Puerto Rico.

Together, these partners collaborate with industry to continue to refine and expand the platform, accelerating commercial adoption and opening new pathways for plastic recovery and reuse.

Learn more about NLR’s bioenergy and bioeconomy research, including its minerals and materials and recovery, reuse, and redesign of wastes plastics research.

Last Updated May 28, 2025