HERO’s Mission: Engineering ‘Video Games’ Meet Wave Tank

Latest HERO WEC Mission Status Update Examines How NREL’s Wave Tank Validates Computer-Generated Scenarios for Wave Energy Converters

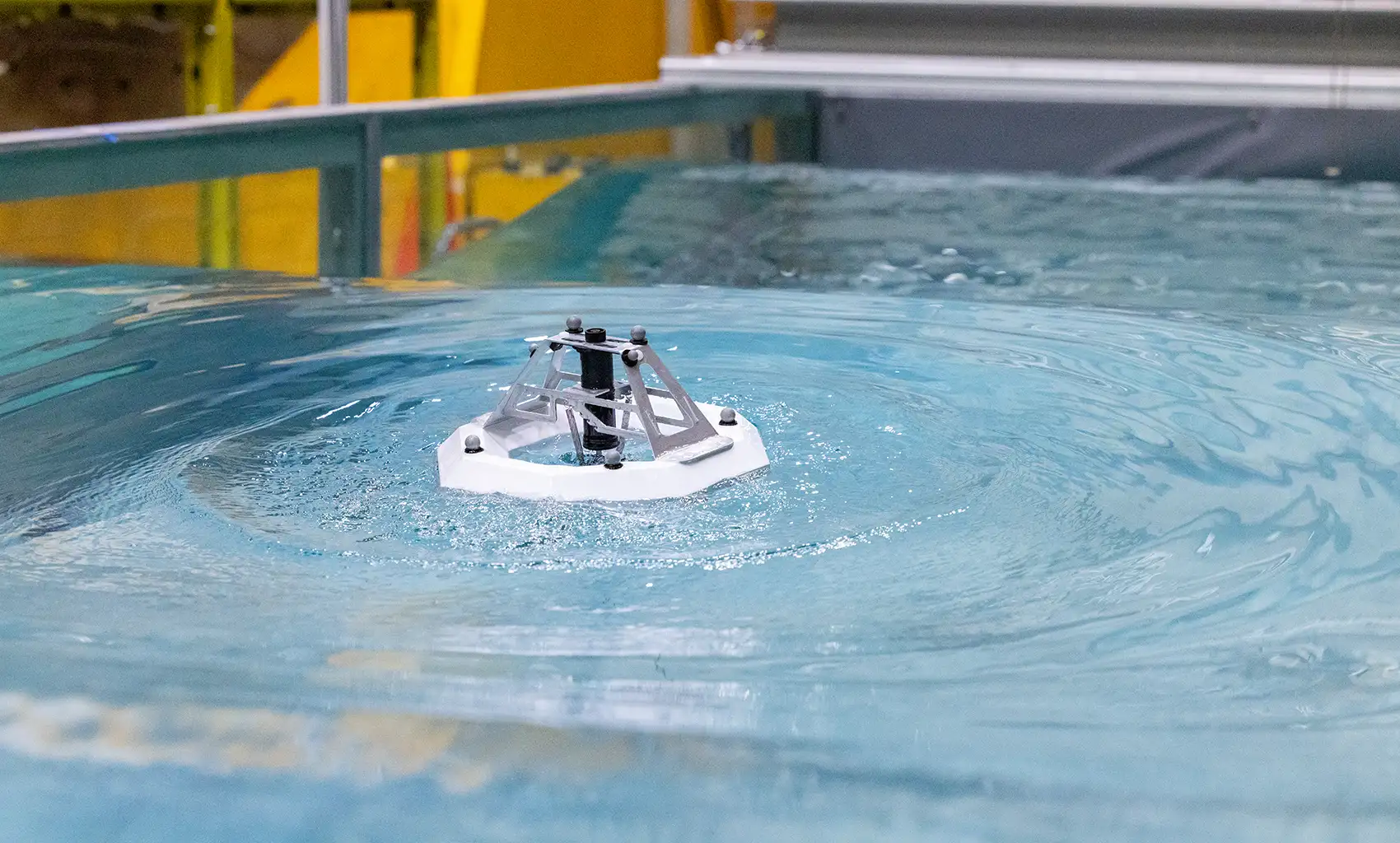

NREL’s hydraulic and electric reverse osmosis wave energy converter (HERO WEC) surfed the laboratory’s wave tank, facing another round of trials and tribulations to advance wave energy research.

Since 2024 the team has been improving the HERO WEC’s robustness, reliability, and deployability by modifying different components on the device and testing the revised design. Researchers have already upgraded the winch line, which both anchors the WEC and allows it to move freely with the waves. In December 2024, they swapped the original wire rope with a polyurethane flat belt that overperformed in initial lab testing. Now, they are focusing on the WEC’s outer body and structure.

The HERO WEC, which is funded by the U.S. Department of Energy's Water Power Technologies Office (WPTO), can operate using either a hydraulic or an electrical configuration to pump seawater through an onshore reverse osmosis system to produce fresh drinking water (a process called desalination).

To help bolster the HERO WEC’s robustness, reliability, and survivability, the team is replacing the inflatable body with a more rigid, shell-like frame and moving the power system components to the top of the float (instead of inside). The original HERO WEC was constrained by the Waves to Water Prize shipping requirements—devices had to fit in a 3.5 x 3.5 x 3-foot container—which is why V1 used a compact, inflatable raft-like design. This original design worked well for two-week deployments, but it would not be able to withstand six months to a year in the harsh ocean environment. That is one reason the team is changing the device’s body for V2.

Changing the WEC’s outer body to a more durable material can help it withstand storms and intense wave conditions. Moving the power system components to a more accessible place can also help improve maintenance and operations. But before solidifying these changes, the team wanted to ensure the accuracy of the computer simulations they used to evaluate the new shell’s efficiency and survivability.

Like video games, engineering simulations use computer-generated environments. But engineering simulations go a step further by modeling and analyzing scenarios. NREL wave energy researchers use two different simulation tools—WEC-Sim and a computational fluid dynamics model—to create computer-generated environments, which predict and analyze how the HERO WEC will behave in real-world ocean conditions. These simulation tools involve complex mathematical models, so it is important to calibrate them and ensure the simulations accurately predict and analyze the real-world scenarios.

Enter: the wave tank. The research team ran these same scenarios using NREL’s wave tank—also known as the Sea Wave Environmental Lab—to track the HERO WEC’s movement, position, and force on the anchor. The tank test data validated the computer-generated simulations and confirmed their accuracy.

After validation, the team does not anticipate needing to put the HERO WEC back in the wave tank. Instead, they will rely on the simulation tools to find the ideal device shape and component configuration that maximizes the WEC’s power generation and water production while minimizing force on the anchor and WEC.

While the HERO WEC V2 model tested in the wave tank was a miniature version (seven times smaller than the planned prototype), it helped researchers answer some big questions, including whether a new frame and component configuration is optimal for the HERO WEC V2.

Validating HERO WEC simulations through wave tank testing also allowed NREL researchers to evaluate WEC testing procedures at large. Specifically, they highlighted how both tank testing and simulation tools can benefit marine energy technologies.

Tank testing can help researchers and technology developers understand early on if their simulation tools need refinement or how sensitive a design is to small tweaks. Certain factors, like the ocean’s resistance to the WEC’s motion, are difficult to calculate but can significantly impact how a prototype performs in the water. Tank testing is a quick and cost-effective way to verify that simulation tools are accurately calculating key factors. The results of these tests can provide critical guidance for researchers and developers before they build a full-scale WEC prototype, a costly step in developing marine energy devices.

The more tests that the HERO WEC team runs, the more they help uncover the best approaches for WEC testing. By developing, refining, and standardizing an efficient testing process, NREL can help guide the marine energy industry as it develops energy conversion devices that are reliable and cost competitive.

With the wave tank test complete, NREL researchers will now focus on building the HERO WEC’s new shell-like body and continue to run simulation models to inform the process.

Stay tuned for more HERO WEC design updates, test results, and project milestones.

Learn more about NREL's research in marine energy and the HERO WEC device and its open-source data. Then, subscribe to The Current—NREL's water power newsletter—to stay up to date on the latest research.

Last Updated May 28, 2025