A Deeper Look at Hidden Damage: Nano-CT Imaging Maps Internal Battery Degradation

The minerals that power lithium-ion batteries—including lithium, nickel, cobalt, manganese, and graphite—are both highly valuable and difficult to come by.

As battery storage capacity across the United States continues to grow, constraints on the mining, refining, and processing of key minerals leaves our energy systems vulnerable to the fluctuations of foreign markets. China maintains significant control across the battery supply chain, including 60% to 90% of global mineral processing for lithium, nickel, and cobalt, according to a recent report from the U.S. Department of Energy.

Direct recycling of battery cathodes within the United States offers an opportunity to strengthen domestic battery supply chains and extend the lifespan of critical materials. However, traditional battery recycling methods are expensive and energy intensive, breaking down materials to their basic elements and rebuilding batteries from scratch.

National Renewable Energy Laboratory (NREL) researchers are exploring an alternative method in direct recycling, which aims to preserve and refurbish battery components for a more efficient and cost-effective process. Unfortunately, not all direct-recycled batteries are created equal. Microscopic and difficult-to-detect damage within cells builds up over time, weakening the performance of some batteries. High-quality recovered materials ensure that recycled batteries achieve the performance and lifetime expected by consumers.

High-Resolution Insights To Improve Recovery

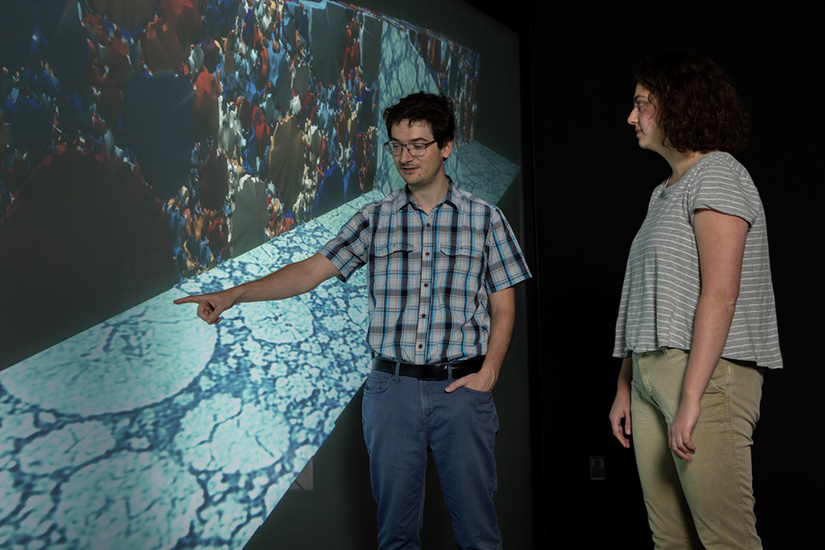

NREL researchers look to X-ray nanoscale computed tomography (nano-CT) imaging of batteries at the end of their useful life to reveal hidden flaws that impact the quality of materials recovered for recycling. NREL’s state-of-the-art nano-CT scanner can achieve an impressive 50-nanometer spatial resolution—an ability typically reserved for high-energy synchrotron X-ray facilities.

This advanced imaging tool allows researchers to analyze the internal structure and composition of energy materials in exceptional detail. Because nano-CT is nondestructive, scientists can observe these changes as they happen in real time, offering essential insights into how battery materials change during operation and cycling.

“This in-house, high-resolution imaging allows us to inspect specific degradation types that exist in end-of-life battery materials,” said NREL’s Donal Finegan, a senior energy storage scientist. “Combined with other microscopy tools and advanced artificial intelligence, nano-CT helps pinpoint barriers facing direct recycling so we can develop techniques to recover and refurbish high-quality materials that maximize battery performance.”

Tiny Cracks, Big Impacts

“Early in this project, we found that the end-of-life material showed a similar energy capacity to pristine, unused battery cells, however, the charging rate was severely diminished,” said Melissa Popeil, an NREL energy storage doctoral researcher. “We were surprised to find that the primary damage type limiting battery performance was morphological changes, or particle cracking within the material microstructure.”

What started as a basic electrochemical performance evaluation quickly expanded to include in-depth characterization of battery cell capacity, composition, morphology, microstructure, and more to determine the extent of degradation. To maintain real-world relevancy, the project looked at commercial battery cells that were cycled under realistic, long-term conditions as part of the U.S. Department of Energy’s Vehicle Technologies Office. Researchers used nano-CT scanning alongside NREL’s Microstructure Analysis Toolbox (MATBOX) to identify and quantify the types of damage within each cell, isolating different layers to maximize spatial variation.

As researchers continue to develop new direct recycling processes, they will need to address these severe cracks in the cathode active materials. Fortunately, NREL researchers are up to the challenge.

“Now that we’ve identified the extent of this cracking, we are evaluating new ways to process the end-of-life material to repair some of that damage,” Popeil said. “By targeting mechanical changes to the material, we can avoid extensive chemical processing in favor of simplified and more efficient recovery methods.”

This research underscores the importance of advanced characterization techniques, such as nano-CT scanning, when determining a future for spent or discarded lithium-ion batteries. Researchers will next expand the project to include a wider range of battery materials entering the waste stream to optimize recycling processes for different battery chemistries, extending the lifetime and value of critical minerals within the U.S. supply chain.

Learn more about NREL's energy storage and transportation and mobility research. And sign up for NREL's quarterly transportation and mobility research newsletter to stay current on the latest news.

Last Updated May 28, 2025