ALTRIOS Software Helps Launch Next-Generation Railcars in Heart of Georgia

Parallel Systems’ Self-Propelled Railcars and a New Dispatching Strategy Could Help Smaller Railroads Compete in Short-Haul Delivery Market

A new kind of freight train has hit the tracks outside of Savannah, Georgia—and researchers at NREL, a U.S. Department of Energy national laboratory, helped put it there.

With approval from the Federal Railroad Association, U.S. manufacturer Parallel Systems launched a seven-phase pilot of its self-propelling railcars this summer along the Heart of Georgia railroad, which is operated by the short-line railroad Genesee & Wyoming.

Traditional freight trains haul large portions of the nation’s long-distance cargo: roughly 1.5 billion tons of raw materials and finished goods every year, or about 118,000 pounds of cargo per American. Yet they struggle to compete in the short-haul delivery market, where they carry just 4% of shipments, compared to the trucking industry’s 75%.

Parallel, a newcomer to the well-established world of freight trains, could change those proportions with railcars that mimic the flexibility and speed of trucks.

With faster, more flexible dispatching to more areas in the United States, freight trains could become more competitive with trucks—reducing traffic and collisions on highways and lowering the cost of deliveries.

Unlike a traditional freight train, which typically uses a group of diesel locomotives to haul 100 railcars or more, each Parallel railcar powers and controls itself using a battery, onboard control system, and a suite of sensors.

The vehicles are capable of “platooning”—connecting themselves using a spring-damper bumper system—to form small 20- to 30-car convoys that travel closely together to reduce aerodynamic drag. These smaller, lighter platoons have the potential to flow through freight facilities far more quickly than traditional trains, reducing bottlenecks and lag time and ultimately getting deliveries to their final destinations faster. It could help make freight trains competitive, for the first time, in the short-haul delivery market.

Parallel’s disruptive concept requires precise engineering, deep understanding of railcar dynamics, and a lot of optimization. That is where NREL researchers come in.

“We want to bring miles back to railroads so railroads can make more money,” said Suzi An, a Parallel project manager. “What NREL has helped us do is put structure and data behind that idea.”

NREL’s Train and Terminal Optimization Tools Identify New Efficiencies

In 2024, NREL commercial vehicle researchers journeyed to MxV Rail’s test facility in Pueblo, Colorado, to observe Parallel rail vehicles on the tracks: watching as the railcars braked, curved, and equalized their weight, then finally zoomed around a high-speed loop track. These evaluations helped ensure Parallel’s railcars met industry standards for train dynamics before demonstrations began along the Heart of Georgia rail line.

In the meantime, NREL researchers could begin optimizing Parallel’s operations.

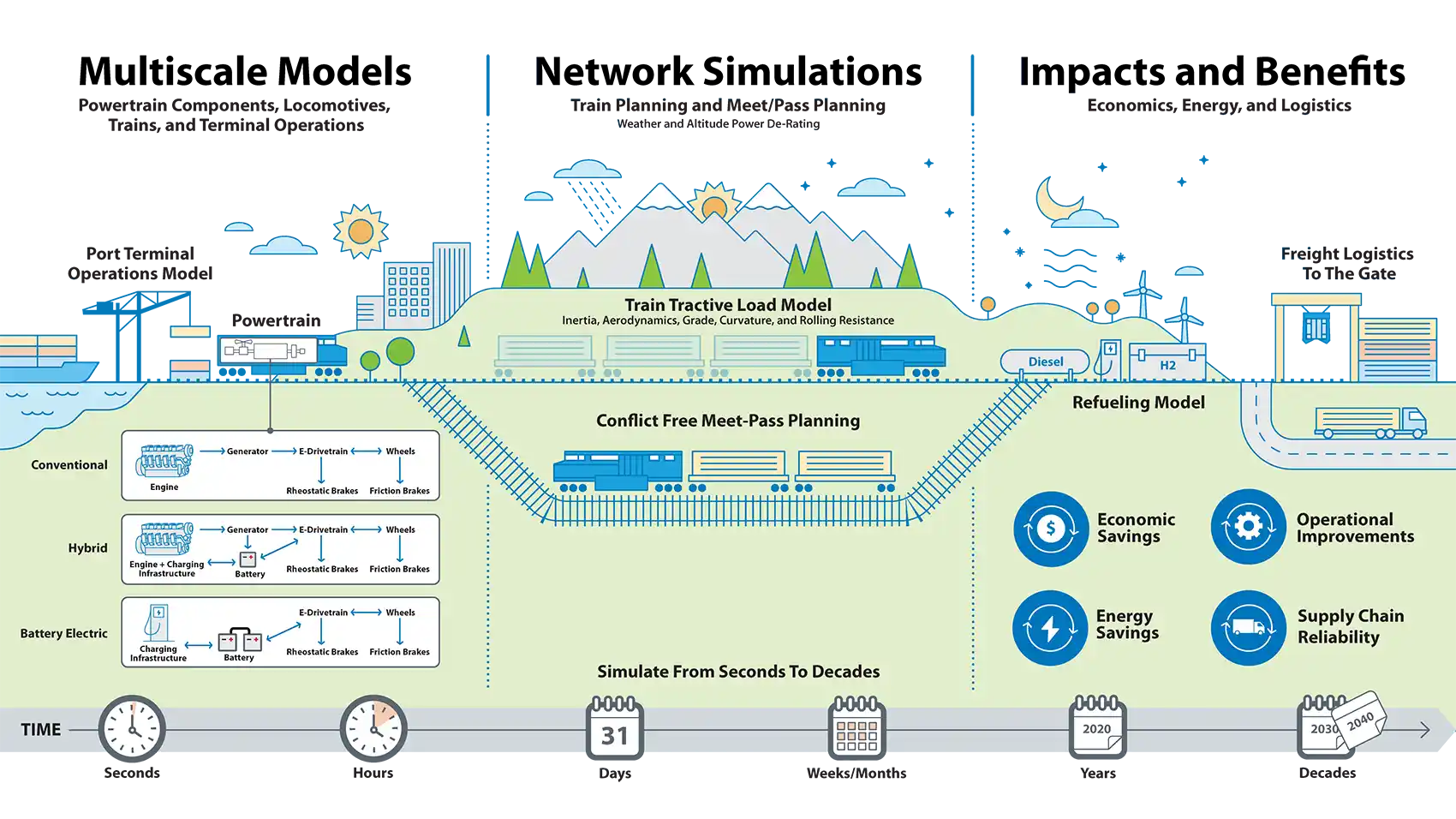

Using data gathered during the evaluations, along with vehicle specifications, the research team built Parallel’s railcars into their open-source Advanced Locomotive Technology and Rail Infrastructure Optimization System, called ALTRIOS.

ALTRIOS operates, in some ways, like a very high-resolution camera. Researchers can use it to see a crisp operational rendering of an entire rail system, including the movements of multiple fleets. Or they can use it to zoom into the fine details of a single train’s operation and even individual components like a powertrain or a set of brakes.

“A very multidisciplinary team built ALTRIOS, and it was important to us that industry partners had a strong voice in its development,” said Jason Lustbader, NREL’s principal investigator for the project.

“We combined fine-grained details of individual component and powertrain performance with a system-level perspective, which is what allows us to model rail traffic, infrastructure constraints, and now terminal operations,” he said. “It enables ALTRIOS to operate at a high fidelity for single trains and entire rail networks and makes it useful to railroads and manufacturers.”

To optimize Parallel’s operations, NREL researchers first simulated Parallel railcars traveling along multiple U.S. routes. Then, they narrowed in on specific interactions. Researchers determined the right battery size to allow vehicles to haul cargo 500 miles on a single charge without adding excess weight or cost. They identified the best platoon length to allow for fast, low-energy deliveries of as many containers as possible. And they determined how many platoons Parallel could dispatch without saturating the rail network.

Next, researchers turned their focus to Parallel’s operations within freight terminals.

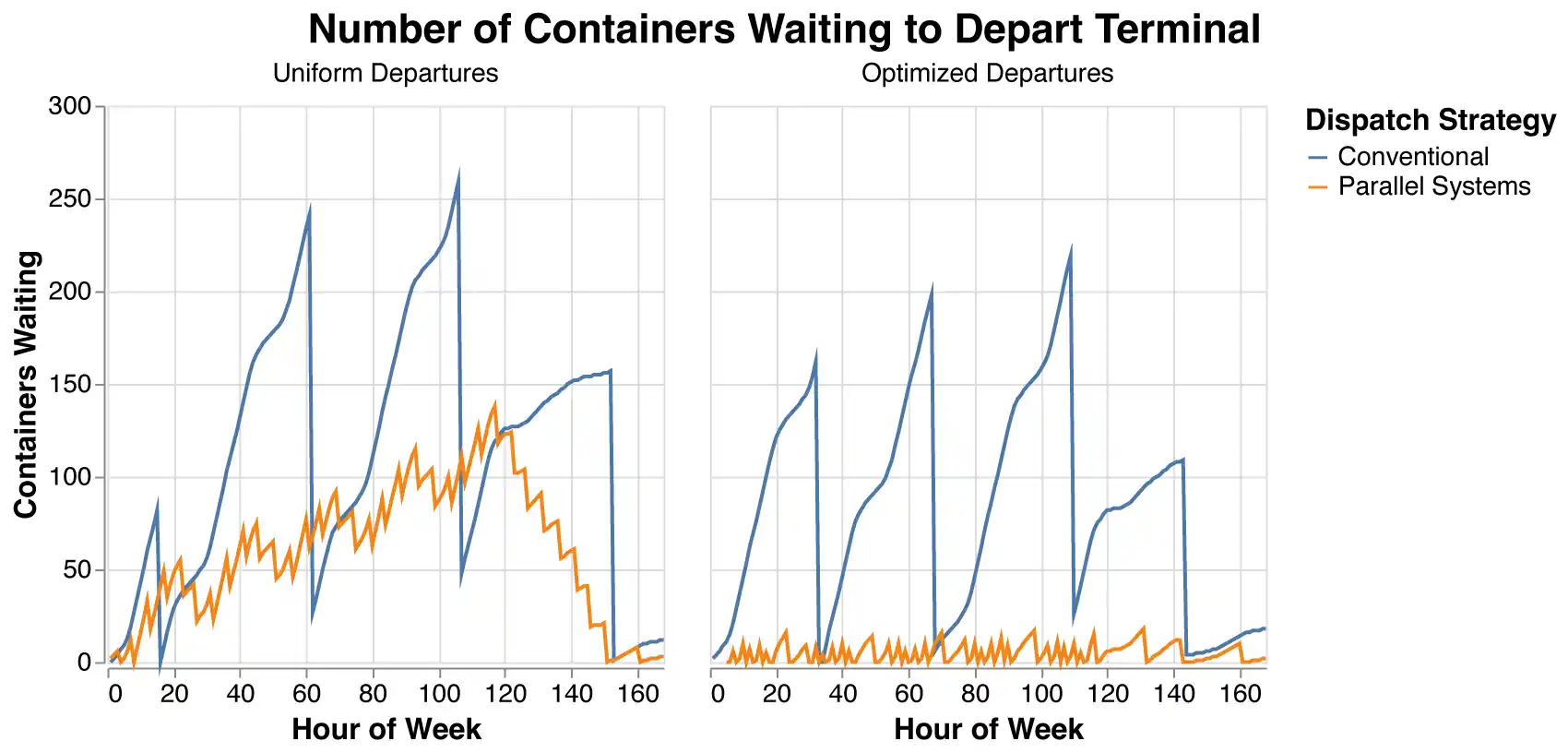

Traditionally, a freight train is “built” by physically coupling railcars together, then using cranes and yard tractors to load them with containers. To reduce the cost of shipping, these trains can stretch over two miles in length—and assembling a train can take hours. Logistics can slow even further due to a dispatching pattern NREL researchers describe as a “sawtooth.” While shipments that arrive just before a train departs can make it onto a train quickly, shipments that arrive afterward may sit for 24 hours or more before being loaded onto the next train.

Parallel and NREL aim to turn that concept on its head.

Together with researchers from the University of Texas at Austin, the NREL team built a brand-new ALTRIOS module called the Line-haul Intermodal Freight Terminal Simulator, or LIFTS. The module allows researchers to understand even the tiniest movements of containers and equipment inside a freight terminal’s gates. Using ALTRIOS-LIFTS, researchers studied the number of times a crane might lift a container, how much energy it takes to move that container through each step of its journey, and where bottlenecks in the process occurred. Because every unneeded movement costs energy—and money—more efficient operations can quickly create cost savings.

Then, they were able to simulate how Parallel’s railcars would function using either a traditional dispatching strategy or a new, optimized approach.

“Automated vehicles, like Parallel railcars, can be essentially scheduled to leave a terminal on demand,” Lustbader said. “As soon as you have enough railcars to create an aerodynamically efficient platoon—say, 20—you can send them out. It gives you a lot of flexibility in how you dispatch and how you optimize your dispatching.”

And that optimized strategy, researchers determined, would allow Parallel railcars to keep up with demand: arriving at a terminal, taking on 20 to 30 shipping containers, and departing within hours. By reducing bottlenecks, Parallel’s system can slash freight train delivery times by nearly 70%.

Fast, Flexible Deliveries Could Help Small Railroads Compete

The benefits of faster cargo delivery stretch far beyond companies and consumers getting their goods more quickly.

First, reducing the amount of storage needed at freight terminals can help create new opportunities to build smaller freight terminals in areas with no existing rail access.

“When you’re intelligently dispatching railcars as fast as possible, you hardly have any cargo buildup at a freight terminal, so you need very little storage space on-site,” said NREL’s Matt Bruchon, another member of the research team. “You can build a less expensive terminal because it doesn’t need a large footprint. That can potentially unlock new locations for freight terminals in areas that have good rail access but don’t have a lot of space.”

It can also help smaller freight terminals, often located in rural areas, compete with larger facilities.

By reducing bottlenecks, Parallel’s system can slash freight train delivery times by nearly 70%.

“In rural communities that have lower demand, the traditional dispatching model is a lot more challenging,” Lustbader explained. “Freight trains need to be big in order to be cost-effective, and you end up seeing trains running less frequently into rural areas.”

But automating and optimizing small platoons in the way Parallel intends to can help rural freight terminals maintain steady operations, even if they have a low volume of cargo.

“Right now, the rail industry tends to focus on high-volume areas because they can build and dispatch large trains, and it’s very cost-effective,” Lustbader said. “In my mind, Parallel’s technologies could really open opportunities for areas that have lower and less consistent volume and expand rail access across the United States.”

Indeed, revitalizing rural rail lines is a stated goal of Parallel’s operations. The final phase of their Heart of Georgia trial aims to show that Parallel vehicles can successfully deliver revenue-generating containers along the 160 miles of track between Pooler, Georgia, and Cordele, Georgia—an area of the state largely served by trucking companies.

Yet with faster, more flexible dispatching to more areas in the United States, freight trains could become more competitive with trucks. Shifting more freight from trucks to trains can also create benefits, like reducing traffic and collisions on highways and lowering the cost of deliveries.

NREL’s Optimization Tools Stretch Beyond the Tracks

Parallel’s pilot is slated for completion in 2026. After verifying that the technology works safely and is ready for commercialization, the manufacturer will be able to apply for regulatory approval and bring in its first customers.

Custom Solutions

NREL partners with fleets, manufacturers, communities, and transportation agencies to conduct customized research, development, and demonstrations of advanced vehicles and technologies.

“It’s been exciting to use our models to inform real-world decisions and exciting to see Parallel take their next step towards commercialization,” Lustbader said. “It shows how the physics-based modeling tools we build can help make technology development and implementation successful.”

And this is not the end of the line for NREL’s ALTRIOS or ALTRIOS-LIFTS software. The tools open possibilities for analyzing advanced technologies, such as automation and cutting-edge powertrains, at seaport and inland port terminals—including the railroads and highways that lead there.

“Optimizing freight operations, whether it’s within a rail terminal or a port or even along our freight networks, can be a huge boon for our global competitiveness,” Bruchon said. “Improving cost, speed, and reliability could really give the U.S. a leg up.”

Learn more about NREL's transportation and mobility research and its specific focus on advanced commercial vehicles. And sign up for NREL's transportation and mobility research newsletter to stay current on the latest news.

Last Updated Jan. 22, 2026