Field Characterization

Various techniques used in the field help to characterize the optical performance of point- and line-focus optical concentrators. The National Renewable Energy Laboratory (NREL) also uses its high-flux solar furnace to test and evaluate concentrating solar power (CSP) components and investigate advanced material processes.

Learn more about the capabilities discussed below by contacting the CSP Research Staff.

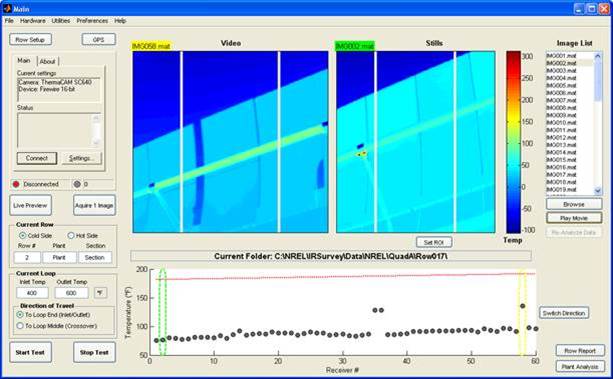

Infrared images of hot and cold tubes as shown on a Thermal Scout screen.

Thermal Scout

Thermal Scout is a sophisticated survey system to rapidly inspect receivers for performance issues. It uses an infrared (IR) camera, global positioning system (GPS) technology, and computer software. The portable system attaches to a standard vehicle that is driven down each row of a parabolic trough plant, using the GPS data to automate IR imaging and analyze temperatures of all receivers in the field. The fully automated Thermal Scout allows operators to safely and more accurately evaluate more than 6,000 receivers per day, without impacting normal plant operation.

A small-scale commercial drone with a specialized camera is part of the Distant Observer photogrammetric data acquisition system, which allows researchers to find flaws in parabolic trough mirrors. (Photo by B. Ihas, NREL 23115)

Distant Observer

Distant Observer (DO) is an optical measurement tool, designed for parabolic trough solar collectors, that determines reflector slope error, absorber position error, and the combined errors based on images of the receiver-tube reflection taken from different angles. We have demonstrated that DO can provide a measurement accuracy of 0.25 mrad for the slope and receiver position errors. DO has two implementation versions: ground-based and drone-driven.

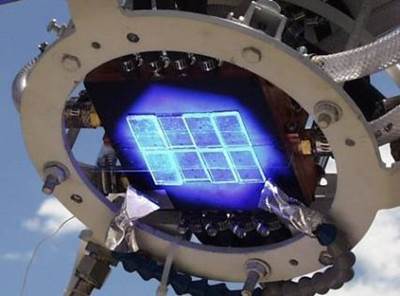

The outdoor UAWS system allows the study of aging on materials, accelerated at up to 100x.

Outdoor Accelerated Weathering

We expose samples to a variety of natural outdoor and accelerated exposure tests to determine their rate of degradation and to estimate lifetime. Typically, we measure samples until they have degraded by 10% of their initial value. Some testing may accelerate outdoor weathering by a factor of 30, helping to identify potential long-term problems. Scientists can then determine failure mechanisms and develop strategies to mitigate possible product failures.

Our outdoor accelerated weathering capabilities include the ultra-accelerated weathering system (UAWS), which is an ultraviolet (UV) concentrator that can simulate 10 years of UV damage in just two months. Studies on aging can be conducted on a wide variety of surfaces—from automotive paint and building materials to coatings on solar panels—by using the UAWS parabolic dish with special mirror facets that concentrate and focus the sun's UV rays. The UAWS won an R&D100 Award for achieving ultra-high intensity and acceleration, high fidelity to actual sunlight, and reasonable exposure temperatures. The UAWS is available to industrial, university, and government researchers. We can provide experienced staff to operate the facility for a variety of experimental objectives.

Share

Last Updated March 26, 2025