Lithium-Ion Battery Chemo-Mechanical Cathode Cracking Model

NLR uses a Python-based software tool to model the anisotropic chemo-mechanics of 3D cathode particles at the grain scale within lithium-ion (Li-ion) batteries to predict aging, particularly in fast-charging conditions.

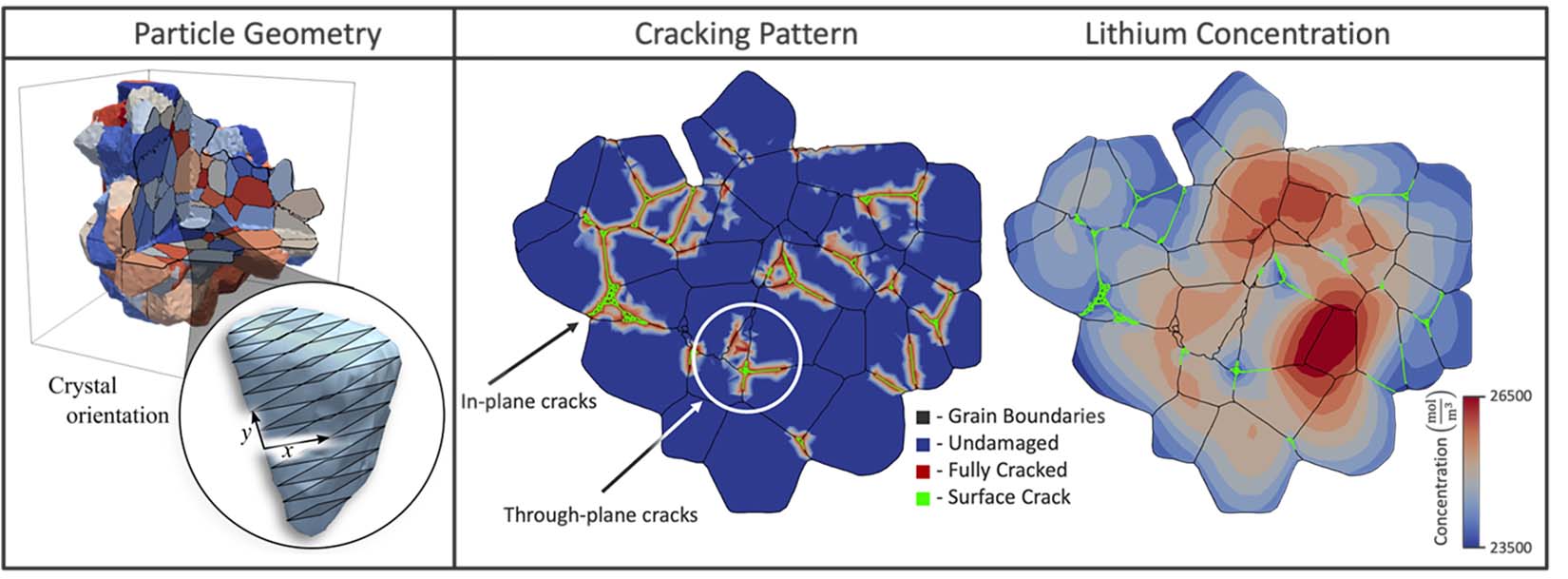

Cracks inhibit Li-ion transport and trigger harmful side reactions that ultimately reduce a battery's lifespan. Our cathode cracking model simulates several charge/discharge cycles of a single polycrystalline particle. The 3D geometry of the simulated particle is generated from Nano-CT images, and captures the distribution of grain orientations that create local stress in the material during charging and discharging cycles, and ultimately lead to macroscopic material cracking.

We have used this model to demonstrate that smaller cathode particles with a few or single-grain architectures experience less capacity loss than larger particles. Additionally, the model includes infiltration of electrolytes into open surface cracks, and thus the effective increase in intercalation surface area. This cathode cracking model remains under active development and is advancing our understanding of degradation mechanisms that lead to battery aging and will inform future robust cathode designs.

Read more about fast charge batteries.

Publications

Quantifying the Influence of Charge Rate and Cathode-Particle Architectures on Degradation of Li-ion Cells Through 3D Continuum-Level Damage Models, Power Sources (2021)

Development Team

NLR's chemo-mechanical cathode cracking model development team includes Jeff Allen, Kandler Smith, Francois Usseglio-Viretta, and Peter Weddle.

Contacts

Share

Last Updated Dec. 4, 2025