Buildings Module

The Stochastic Energy Deployment System Lite Building Module (SLBM) covers both commercial and residential buildings at the U.S. national level. It uses an econometric forecast of floorspace requirement and a model of building stock turnover as the basis for forecasting overall demand for residential and commercial building services, such as heating, cooling, lighting, etc.

The module is an engineering-economic model with technology adoption decisions based on cost and energy performance characteristics of competing technologies with three stages:

- Passive building systems, e.g. insulation

- Active systems, e.g. lighting equipment

- On-site generation, e.g. photovoltaics (PV).

Interactions between technologies—such as insulation lowers heating and cooling requirements—are considered, and service demand is estimated in physical units not energy, e.g., lum-hrs/year instead of kilowatt-hour.

Focus of Analyses

The effects of new passive measures—such as new windows, efficiency standards, carbon taxes—and performance improvements due to R&D are the most suitable scenarios that can be analyzed with the SLBM. These scenarios can be simulated individually or together to evaluate their effects on technology market penetration, energy demand, and the resulting carbon emissions.

Limitations of Analyses

A shortcoming of the buildings sector is that it does not have the regional granularity to capture early deployment of energy efficiency measures in markets burdened by high energy costs. Instead, deployment is based on national averages of energy costs, which can give a conservative estimate of deployment of energy-saving technologies.

Commercial and residential buildings are considered on a U.S. national level and are not further disaggregated into more detailed categories like offices, hospitals, retail stores, detached houses, apartment and mobile homes at this point. Energy service demands per unit floorspace, such as space heating or lighting, can be changed by the user to reflect different consumer behavior based on new or changed policy objectives or changed environmental constraints.

Currently, the most restricted area within SLBM is the decision-making process, which is always based on a levelized cost and logit approach. However, different approaches are tested, and it is expected one will be added for lighting soon. Different approaches are already implemented in the PV module of SLBM.

Another important limitation is the treatment of multiple services from one technology, such as combined heat and power. However, an important advantage is the consideration of internal heat gains due to lighting and plug loads, which can decrease the natural gas load. Internal heat gains decrease the demand for heating in winter, and in large commercial buildings in some climates, internal heat gains are the dominant source of cooling demand in the summer. These effects confound rigid concepts of energy services.

Technologies of Interest to U.S. Department of Energy

The technologies of potential interest to the U.S. Department of Energy (DOE) that the building sector tracks are:

- Lighting, e.g., fluorescent, compact fluorescent lamp (CFL), LED, halogen, etc.

- Heating, e.g., high-efficient, Annual Fuel Utilization Efficiency (AFUE) heating systems

- Hot water technologies

- Refrigeration technologies

- Plug loads

- Ventilation technologies

- Passive technologies, e.g., daylighting or natural ventilation, as well as

- Onsite generation, i.e., PV.

For a full list of currently used technologies, see Table 1 below. Please note that almost any technology can be defined within SLBM. Therefore, Table 1 shows the set of technologies being used at this point.

| Commercial Sector | Residential Sector |

|---|---|

Passive "Technologies"

| Passive "Technologies"

|

Lighting

| Lighting

|

Refrigeration

| Refrigeration

|

Domestic Hot Water

| Domestic Hot Water

|

Ventilation | Ventilation |

Other Load | Other Load |

Space Heating

| Space Heating

|

Space Cooling

| Space Cooling

|

On-Site Generation

| On-Site Generation

|

Overview of Methodology

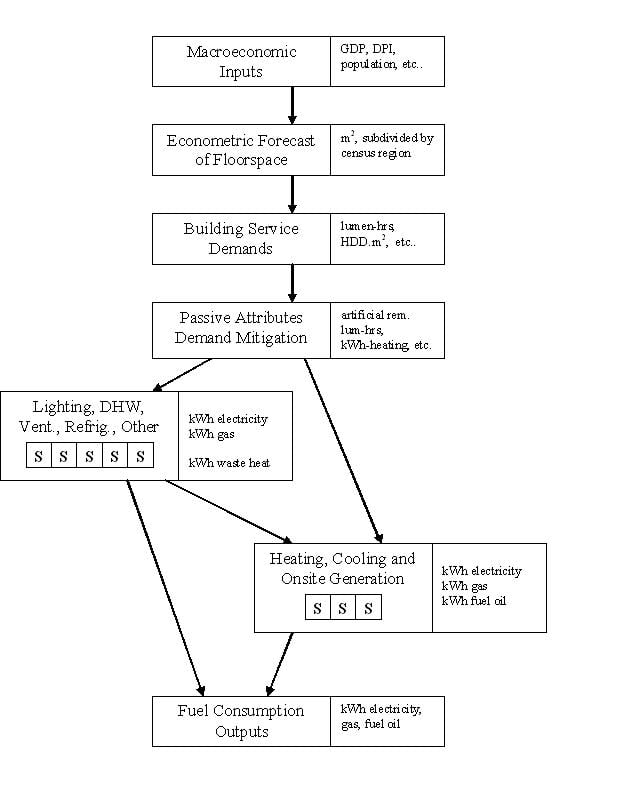

The residential and commercial sectors can be thought of as a series of stock turnover models (T in Figure 1 below) running in parallel that track equipment characteristics and market share as time progresses.

Figure 1. Main SLBM calculation steps

The stock of equipment required is determined by the overall demand for its services, e.g. lum-hrs/year. At each time step, a series of calculations are performed that take input macroeconomic data and fuel prices and output estimates of fuel consumption requirements for provision of a set of building services, i.e., lighting, domestic hot water, ventilation, refrigeration, other loads, heating, and cooling. Those calculations are performed as follows:

- The total demand for floorspace for residential and commercial buildings is forecasted using a simple linear multivariate econometric regression model with the following independent variables: gross domestic product, population, a time lag, and disposal personal income.

- A building stock model determines required new construction at each time step to meet floorspace demand. The floorspace stock model also tracks demolition based on average building lifetimes.

- Current floorspace is multiplied by the expected service demand intensities to arrive at the total raw service demands. In the case of heating and cooling, floorspace is disaggregated by climate region so that heating and cooling degree days can serve as appropriate service intensities.

- The total raw service demands are adjusted for the influence of passive technologies, such as insulation and daylighting, as well as other mitigating factors, such as internal heat gains and infiltration.

- The residual service demands are passed on to specific stock models as these must be met by active, i.e. fuel consuming, technologies.

- Every service-specific stock model tracks the amount of each technology available at each time step considering retirements, and calculates how much new equipment will be needed.

- The amount of each type of new equipment put into service is determined by an engineering-economic calculation using a logit function to determine market shares. The logit computes a market share based on the technology's levelized costs of service. Capital, and accordingly, the levelized costs can be decreased by R&D and learning. The effects of R&D are treated with uncertainty and can be adjusted to try to capture the level of governmental activities in R&D. The combination of all these factors produces a levelized cost on a service basis that is used to determine how the market share of new capacity additions will evolve.

- Fuel type, efficiency, and technology market share are then used to determine total fuel consumption.

- Fuel consumption is then offset by on-site generation with or without combined heat and power as appropriate.

- Fuel consumption is summed across all demand-specific stock models to yield total fuel demands.

- Finally, residential and commercial fuel demands are summed to total SLBM fuel consumption.

After the sequence defined above has been executed for each time step, the projections of floorspace, service demands, technology market share and quantities, energy consumption, and fuel use are available for examination and interpretation. However, if any of the macroeconomic or other inputs are based on a probabilistic distribution rather than scalar values, the model runs multiple times with Monte Carlo draws.

The module tracks the capacity and characteristics of different end-use / onsite generation technologies throughout the simulation as listed and grouped by their energy service category in Table 1 above.

Major Assumptions

Historical floorspace input data are based on commercial and residential energy intensity indicators based on Pacific Northwest National Laboratory's Energy End-Use Flow Maps for the Buildings Sector and DOE's Residential Energy Intensity Indicators.

The final energy demand data—obtained from Pacific Northwest National Laboratory, the Commercial Building Energy Consumption Survey (CBECS), Residential Energy Consumption Survey (RECS) as well as the 2005 Annual Energy Review—for each fuel were divided by the SLBM floorspace estimates for 2005 and used for service demand forecasting.

Equipment types were considered for refrigeration, space cooling, space heating, lighting, water heating, and ventilation. All other end-uses were categorized as plug loads. The installed equipment stock information is based on Lawrence Berkeley National Laboratory's (LBNL's) own calculations derived from appliance manufacturers' shipments data, CBECS, RECS, and Annual Energy Outlook 2007/8: With Projections to 2030.

Portfolio Decision Support Inputs

The building sector is using several expert assessments on end-use technologies, its capital costs and performance characteristics for several different DOE program goal years and different levels of government sponsored R&D. The first technologies that consider portfolio decision support are lighting and PV.

Stochastic Inputs

The building sector has numerous stochastic inputs that relate to one of three categories: policy, capital costs or performance of end-use technology. Policy inputs relate to efficiency standards of end-use appliances and level of passive measures. Capital cost inputs effect the timing and magnitude of improvements in capital costs due to government sponsored R&D. Performance inputs effect the timing and magnitude of improvements in energy conversion factors due to government sponsored R&D.

Key Inputs from Other Modules

- Price of electricity, natural gas, and fuel oil (heating oil)

- Gross domestic product

- Population

- Disposable personal income

Key Outputs to Other Modules

- Demand for electricity, natural gas, and fuel oil

- Carbon emissions

Other Inputs

- Climate conditions (e.g., heating degree day, cooling degree day) for the nine U.S. Census regions

- Policies that influence the service demand

- Passive parameters of commercial and residential buildings (e.g., U-Value)

- Technology parameters (e.g., capital costs, lifetime, efficiency) for end-use technologies

- Estimation of decision-making process for the different technologies for the different sectors (i.e., logit function parameter alpha)

- Initial technology penetration for first simulation year

Other Outputs

- Technology penetrations to 2050

- Carbon emissions from every service (e.g., heating)

Further Information

A Buildings Module for the Stochastic Energy Deployment System

Attachments

SEDS Buildings Module: Text Boxes Added in Building Services Demand Submodule

Authors

Project Lead: Chris Marnay, LBNL

Technical & Programming Lead: Michael Stadler, LBNL & Center for Energy and Innovative Technologies – Austria

Programming & Model Design / PV: Ryoichi Komiyama, LBNL

Lighting Data: Inês Lima Azevedo, LBNL and Department of Engineering and Public Policy, Carnegie Mellon University

Programming & Model Design: Sam Borgeson, LBNL

Programming & Model Design: Brian Coffey, LBNL

Data: Judy Lai, LBNL

Share

Last Updated July 8, 2025