Using Molecular Modeling To Improve Pulp and Paper Manufacturing

NREL partners with industry experts and employs advanced molecular simulations to increase kraft pulp yield by identifying the mechanisms by which softwood is degraded and protected by a novel pretreatment technology.

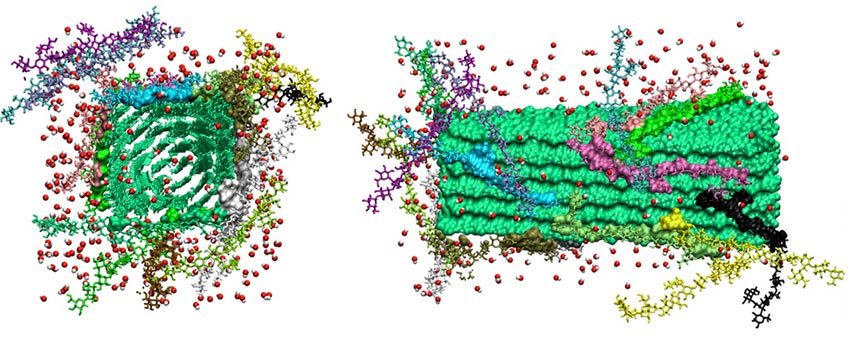

Left: Molecular model of individual chains of hemicellulose (purple and red sticks representation) interacting with a cellulose microfibril (green surface, with chain ends shown in green and red sticks). Right: Snapshot of cellulose microfibril (green surface representation) complexed with galactoglucomannan (GGM) chains (various colors) following 300 ns MD simulation. Bound GGM residues are shown in solid surface model, and unbound GGM residues are shown in stick representation. Hydroxide ions (dissociated from NaOH and responsible for "peeling" of sugars from polysaccharide chain ends) are shown as spheres (red: oxygen, white: hydrogen). Photo by NREL

In partnership with the Alliance for Pulp and Paper Technology Innovation and Oak Ridge National Laboratory, NREL performs computer simulations that help the American pulp and paper industry determine how softwood can be pretreated to more effectively preserve the wood components, thus increasing yield and decreasing the manufacturing cost of wood pulp for paper. This research explores how chemical adjustments in the manufacturing process could result in increased mill profitability and decreased energy costs.

This research uses molecular dynamics simulations and quantum mechanical mechanism studies to analyze the detailed chemical mechanisms of peeling reactions during kraft pulping and pretreatment reactions that protect polysaccharide chain ends.

Impact

Insight provided by this project could guide industry partners to adjust the chemistry and manufacturing process to increase pulp yield. With comprehensive computational modeling and analysis, industry experts can use the theoretical results provided to make informed decisions and investments.

Publications

The Molecular Basis for Protection of Reducing End Groups in Wood Carbohydrates for Kraft Pulping Revealed by Computation, Unpublished article (2020)

Partners

Alliance for Pulp and Paper Technology Innovation

Contact

Share