NREL’s Recyclable Carbon Fiber Composites Made Greener With Thermoforming

Recycling Advancement Reduces Costs and Greenhouse Gas Emissions of Material’s Second Life by 90% to 95%

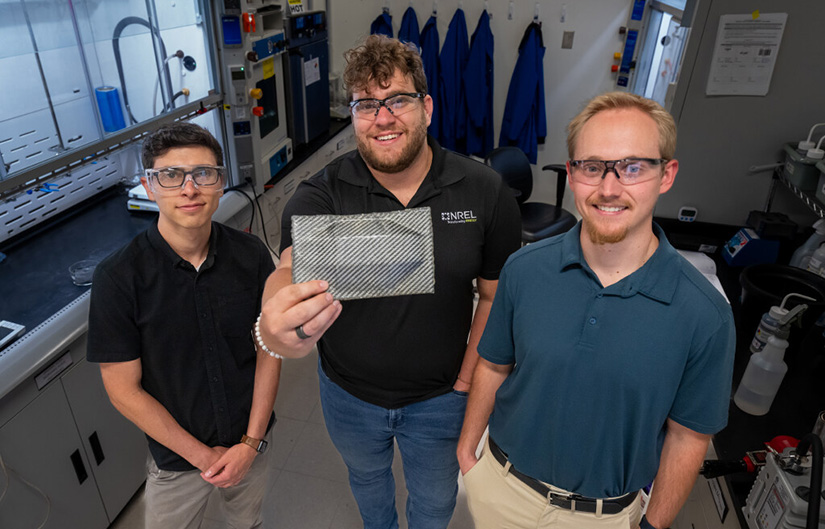

Jason DesVeaux, Nic Rorrer, and Erik Rognerud (left to right) used thermoforming to add multiple curvatures to a recyclable carbon fiber composite sample. This material can be used instead of steel in electric vehicles to improve energy efficiency. Image by Werner Slocum, NREL

Nicholas Rorrer does not describe himself as a car guy. Even so, new advancements in his research developing recyclable carbon fiber composites using bio-derivable epoxies represent some of the most promising solutions yet for decarbonizing the vehicle manufacturing process and beyond.

“Vehicles are a real driver, pun intended, of the materials economy. To me, they represent nearly endless opportunities in materials design—not only to make the first generation of a material better but to also improve upon those designs in future generations,” said Rorrer, who is a senior polymer science researcher and group manager at the National Renewable Energy Laboratory (NREL).

Rorrer currently leads a team of NREL researchers working to replace the heavy, resource-intensive steel parts in vehicles with recyclable carbon fiber composites. The ongoing project is supported by the U.S. Department of Energy's Vehicle Technologies Office under the Composites Core Program in the Materials Technology subprogram.

The Key to Earth-Friendly Carbon Fiber Composites

When used in place of steel in vehicle components like hoods and roofs, carbon fiber composites can reduce the weight of a typical passenger car in half—boosting fuel efficiency by up to 35%—without sacrificing strength. This swap can free up weight and space for bigger batteries in electric vehicles, resulting in longer ranges and better energy efficiency.

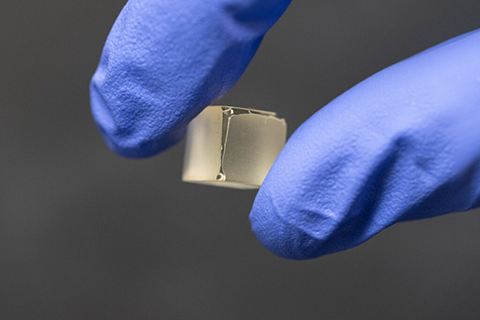

A researcher holds a small cube of resin used in NREL’s recyclable carbon fiber composite. Image by Werner Slocum, NREL

But the benefits of traditional carbon fiber composites stop there. The material’s manufacturing processes are energy, greenhouse gas (GHG) emissions, and cost intensive, canceling out any environmental benefits.

“Traditional carbon fiber composites cost too much, are too brittle, and have high GHG emissions. Vehicle manufacturers aren’t interested in using them,” Rorrer said. “But transitioning to lighter vehicles using more affordable, strong, and Earth-friendly carbon fiber composites can be an important part of decarbonizing the transportation sector.”

In fact, carbon fiber composites made with NREL’s polymer science and engineering bio-derivable resin can be recycled at least three times. And a recent breakthrough by the NREL team may make their reuse even more cost and energy efficient.

“This is huge,” said NREL’s Erik Rognerud, a research technician on the project. “This technology could finally make carbon fiber affordable for consumer vehicles, which means cars will have better gas mileage or longer driving ranges. Carbon fiber composites will save money at the pump or by charge and reduce carbon dioxide in the environment.”

A More Efficient Recycling Process

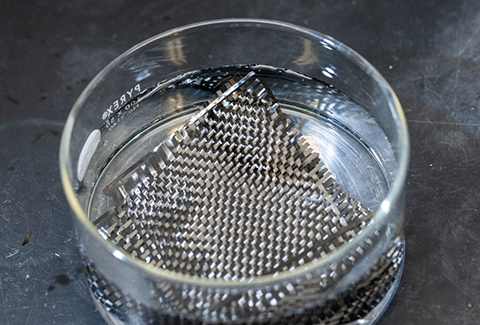

Components of NREL’s recyclable carbon fiber composite separate at room temperature in a depolymerization bath. Image by Werner Slocum, NREL

NREL’s recyclable carbon fiber composites are made up of bio-derivable epoxies, anhydride hardener, and carbon fibers. Rorrer and his team initially used a multistep process called methanolysis to prove the material’s recyclability. The application of this process represented the material’s first step toward circularity, a model of production and consumption that extends the life cycle of products—making the carbon fiber composites cheaper and greener when used across multiple lives.

In methanolysis, an inexpensive catalyst is added at room temperature to trigger chemical depolymerization, a process that causes the components to separate. Researchers can then reclaim the original carbon filaments for reuse with new bio-derivable epoxies and anhydride hardener.

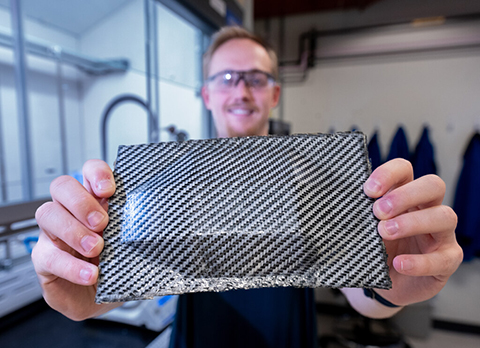

“With thermoforming, you can skip all of that,” Rorrer explained, referring to the process of separating the material’s components in methanolysis. The impact of this work is detailed in the NREL presentation, Bio-Based, Inherently Recyclable Epoxy Resins to Enable Facile Carbon-Fiber-Reinforced Composites Recycling. “We have shown that you can simply press the material into different shapes to reuse them. And when you use both chemical depolymerization and thermoforming, you can reduce the cost and GHG emissions of the material’s second life by 90% to 95% compared to the first life of the material.”

The NREL team’s thermoforming process saves time and energy by allowing the material to stay intact. In thermoforming, researchers heat the recyclable carbon-fiber-reinforced composite to just above the boiling point of water and press it between two molds to shape the material for its next use.

But Rorrer and his team are not finished improving the material’s recycling process. The team is continuously exploring strategies for making thermoforming even easier, faster, and more energy efficient.

More Advancements Ahead

Erik Rognerud holds up a thermoformed sample of the research team’s recyclable carbon fiber composite. Image by Werner Slocum, NREL

Rorrer is determined to continue developing NREL’s recyclable carbon fiber composites as a cost-effective, lightweight, and environmentally friendly alternative to steel. Beyond its use in vehicles, the team is studying the material’s performance in applications like wind turbine blades. Future partnerships also present the opportunity to unlock additional applications by considering other manufacturing processes.

“In the first phase of this work, we focused on reducing the environmental impacts of the material’s subsequent lives,” Rorrer said.

In the next phases, the team will look for ways to reduce the environmental impacts and improve the performance of the material’s first life.

“We really want to develop a technology that automobile manufacturers would be excited about using broadly,” he said. “I think the next challenge after this phase of work, or even possibly as a part of this phase of work, is to make sure that our materials can be transformed into prototypical parts through today’s manufacturing requirements.”

Learn more about NREL's sustainable transportation and mobility research and its specific focus on transportation decarbonization. And sign up for NREL's quarterly transportation and mobility research newsletter, Sustainable Mobility Matters, to get the latest news.