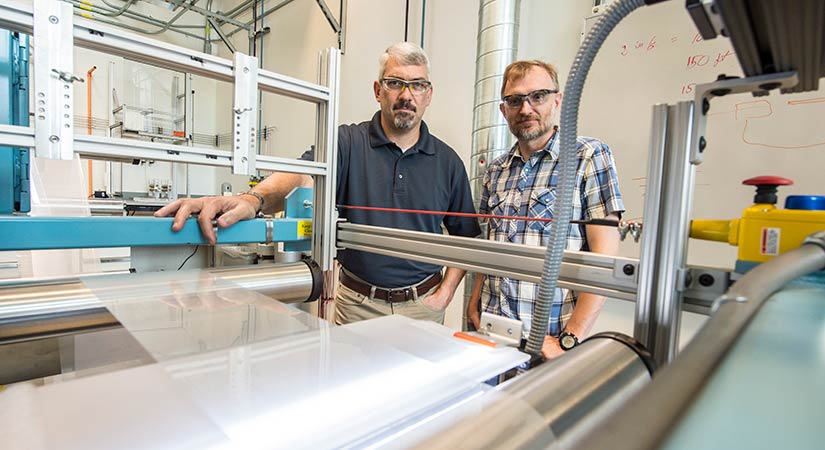

Roll-to-Roll Manufacturing

NREL's research in advanced roll-to-roll technologies and processing techniques is used to produce clean energy technologies to help reduce costs and increase precision.

Capabilities

NREL supports advanced manufacturing through roll-to-roll-related capabilities and projects.

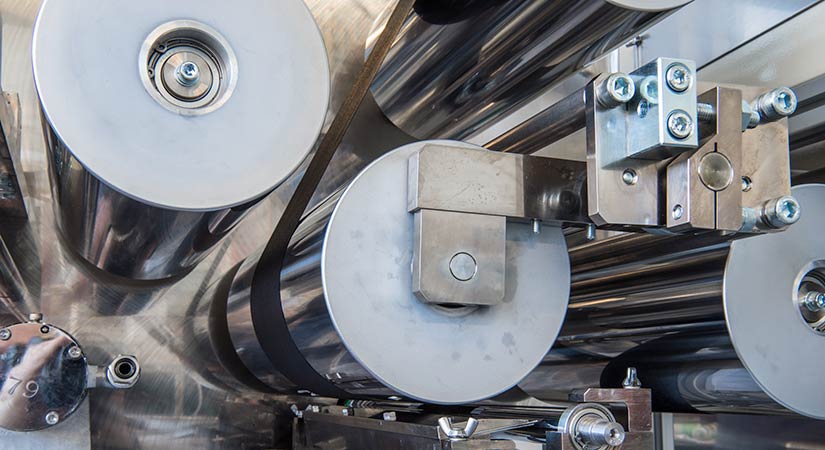

Roll-to-Roll Manufacturing Multilab Collaboration

In a multilab collaborative effort, NREL researchers are accelerating roll-to-roll materials manufacturing for a broad range of energy-, water-, and industry-related technologies to lower costs and improve efficiency. Our roll-to-roll manufacturing research uses various U.S. Department of Energy funding mechanisms and spans several technology areas.

Hydrogen Fuel Cells

NREL works with industry to optimize roll-to-roll manufacturing for low-cost water electrolyzers to reduce manufacturing cost and labor. These efforts could result in more affordable hydrogen production via proton exchange membrane electrolysis.

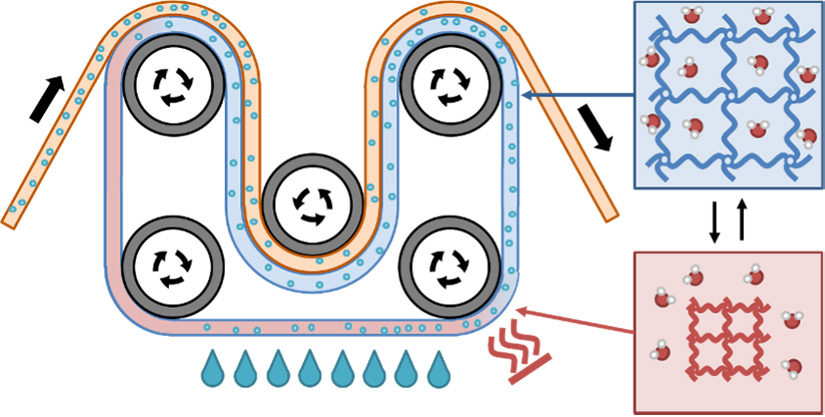

Non-Evaporative Drying of Porous Materials

NREL researchers and collaborators are helping the paper manufacturing industry save energy and water with a novel non-evaporative drying process using polymer chemistry. This research is possible due to funding from the U.S. Department of Energy's Industrial Efficiency and Decarbonization Office.

Share