Dual-Beam Sample Preparation

NREL uses a dual-beam focused ion-beam (FIB) workstation for ion milling, metal deposition, ion imaging, and electron imaging on the micrometer and nanometer scale of advanced photovoltaic materials and devices.

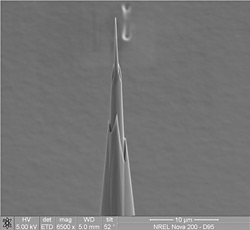

NREL's dual-beam focused-ion beam workstation for fabricating microscopy samples and nanostructures.

The dual-beam FIB supports other analytical tools such as transmission electron microscopy (TEM), and precise, site-specific sample preparation for TEM, SEM, and local electrode atom probe (LEAP). See below examples.

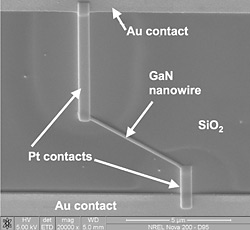

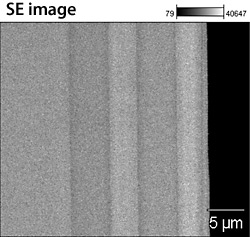

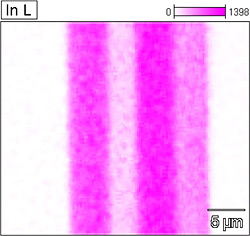

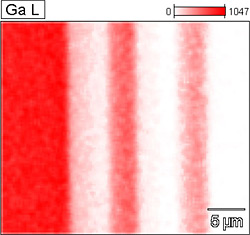

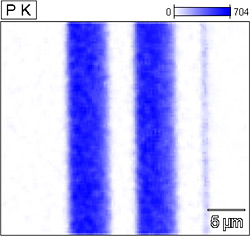

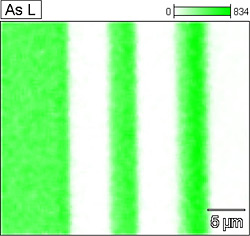

Acquiring chemical spectra and elemental maps is another feature of this system with energy-dispersive spectroscopy (EDS). Three-dimensional chemical reconstructions can be obtained by combining controlled ion milling with chemical mapping. The FIB is equipped with a gas injection system (GIS) platinum metal deposition capability that can be used with either ion-beam-assisted or electron-beam-assisted chemical vapor deposition. Using a digital patterning generator also allows for complete FIB milling or deposition of complex structures with software-supplied parameters or by direct input of bitmap files (or both). See below examples.

Examples of Dual-Beam Focused-Ion-Beam Sample Fabrication Capabilities

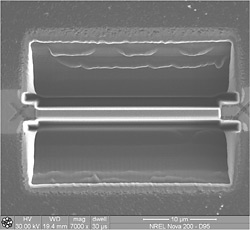

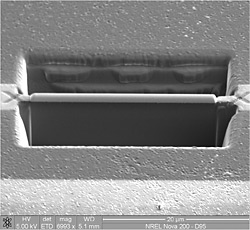

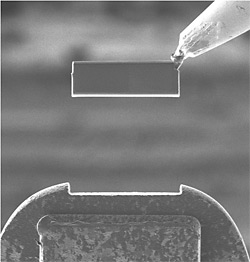

FIB: TEM sample preparation — FIB prepared TEM cross-section (from A to C). Opposing trenches are milled out with the Ga+ ion source and a 1-2 µm thin section is left free standing in the wafer. A side view shows the depth of the trenches. The section is then welded to the micro-manipulator, extracted from the wafer then transferred and welded to a TEM grid post. Final thinning down to a thickness of < 100nm is achieved using low incident angles and low Ga ion current.

Contact

Share