Contaminants

At NREL, we are researching system-derived contaminants and hydrogen fuel quality. Air contaminants are of interest as well.

Material Screening Data Tool

Explore the results of fuel cell system contaminants studies.

As fuel cell systems become more commercially competitive, and as automotive fuel cell research and development trends toward decreased catalyst loadings and thinner membranes, fuel cell operation becomes even more susceptible to contaminants.

System-Derived Contaminants

System Contaminants Project Overview

Contaminants derived from fuel cell system component materialsstructural materials, lubricants, greases, adhesives, sealants, and hoseshave been shown to affect the performance and durability of fuel cell systems. NREL is performing research to identify and quantify these system-derived contaminants and to understand the effects of system contaminants on fuel cell performance and durability. Our goal is to increase the understanding of fuel cell system contaminants and to help guide the implementation and, where necessary, development of system materials that will help enable fuel cell commercialization.

Between July 2009 and September 2013, NREL led a team to study the effect of system contaminants on the performance and durability of polymer electrolyte membrane fuel cells. The team, made up of industry, university, and national laboratory partners, screened about 60 balance of plant (BOP) materials using several screening methods. The materials are from different manufacturers, comprise different chemistries, and are used for different functions.

In order to make the results of this work more useful to the fuel cell community, NREL has designed an interactive material screening data tool to archive the results from these studies and make them publicly accessible. Knowledge of the material contamination potential of various system components can be used by the fuel cell industry in selecting appropriate BOP materials and in cost-benefit analyses.

This project was funded by the Fuel Cell Technologies Office in DOE's Office of Energy Efficiency and Renewable Energy.

Contact Huyen Dinh for more information on this project.

Materials Studied

Our initial focus has been on commercially available commodity materials with a range of costs. These materials are generally developed for other applications for which common additives/processing aids may not be a concern, but they may present problems for fuel cells.

We chose materials based on several criteria: physical properties (able to withstand fuel cell operating conditions), commercial availability, cost, processability for high volume manufacturing, and input from original equipment manufacturers (OEMs) and fuel cell system manufacturers.

| Function Description | Chemical Description | Manufacturer | Total Grades |

|---|---|---|---|

| Structural Plastic | Polyamide (PA), polyphthalamide (PPA) (Nylon) | DuPont, EMS, BASF | 22 |

| Structural Plastic | Polyphenylene sulfide (PPS) | Chevron Phillips | 4 |

| Structural Plastic | Polysulfone (PSU) | Solvay | 2 |

| Structural Plastic | Polyphenylsulfone (PPSU) | Solvay | 1 |

| Structural Plastic | Polybutylene terephthalate (PBT) | DuPont | 2 |

| Structural Plastic | Epoxy | Sumitomo | 1 |

| Structural Plastic | Phenolic | Sumitomo | 1 |

| Lubricant/Grease | Perfluoroalkylether/ polytetrafluoroethylene (PFAE/PTFE) | DuPont | 4 |

| Adhesive/Seal | Urethane | 3M, Bostik, Henkel | 6 |

| Adhesive/Seal | Silicone | 3M | 2 |

| Adhesive | Epoxy | 3M, Reltek | 3 |

| Adhesive | Acrylic acrylate | LORD | 1 |

| Thread Lock/Seal | Polyglycol dimethacrylate (PGDMA) | Henkel | 4 |

| Thread Sealant | Diacetone alcohol | RectorSeal | 1 |

| Thread Sealant | Polytetrafluoroethylene (PTFE) | LA-CO | 2 |

| Hose | Silicone | Venair | 2 |

Screening and Characterization Methods

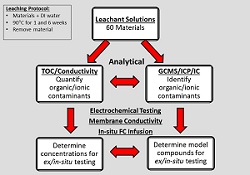

The project team used multiple screening techniques and characterization methods to obtain the data.

- Leaching method

- Ex-situ characterization

- Solution conductivity and pH

- Total organic carbon (TOC)

- Gas and liquid chromatography mass spectrometry (GCMS, LCMS)

- Inductively coupled plasmaoptical emission spectroscopy (ICP-OES)

- Ion chromatography (IC)

- Membrane conductivity

- Cyclic voltammetry (CV)

- In-situ infusion fuel cell testing

The team also performed fundamental studies of selected organic model compounds that were found in the leachates.

Material Screening Data Tool

NREL has designed an interactive material screening data tool to help fuel cell developers and material suppliers explore the results from these studies, which were performed in collaboration with General Motors, the University of South Carolina, and the Colorado School of Mines. To use the tool, select from the drop-down lists of materials to see the screening data collected from multiple methods. You can also view the data tables.

System Contaminants Project Partners

Between July 2009 and September 2013 the project team included the following members:

- NREL

- General Motors

- University of South Carolina

- University of Hawaii

- Colorado School of Mines

- Los Alamos National Laboratory

- In-kind partners

- 3M

- Ballard Power Systems

- Nuvera

Publications and Presentations

Download a list of all publications and presentations related to NREL's fuel cell system contaminants project.

Also view publications from other research groups studying the effects of fuel cell contaminants:

Share